Is laser -cut acrylic healthy hazard?

is laser cutting acrylic toxic?

laser cutting acrylic is one of the latest developments in our technology, making the manufacturing process of acrylic sheets more efficient and providing unparalleled precision when engraving, engraving or shaping. this high-performance technology opens up a world of creative possibilities.

however, today we won’t extol the power of laser cutting acrylics. instead, in this article, we'll explore the safety considerations of this technology and find out whether it's toxic. we will also provide safety measures and guidelines to follow before taking the project onto site.

it is important to understand and follow safety precautions. let’s take a look at whether and how effectively laser cutting acrylic has revolutionized manufacturing.

a brief overview of laser cutting acrylic

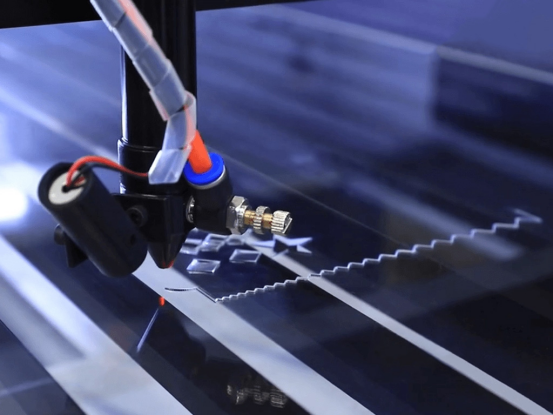

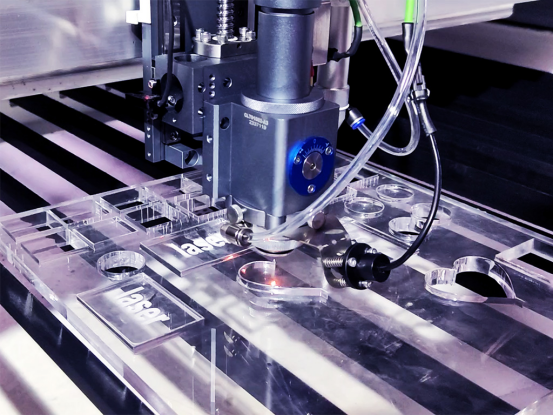

laser cutting acrylic uses a high-voltage concentrated laser beam to cut the material. it offers a wide range of applications. the laser beam precisely cuts or engraves the acrylic sheet. this is much better than traditional milling or sawing methods. efficient productivity and ease of use make laser cutting acrylic sheets popular today.

the intense heat generated by the laser is used to cut and shape the material, giving it a smooth surface and clean edges.laser cutting machineprovides superior accuracy for the task.

learn about safety considerations and importance

this added technology is undoubtedly more beneficial than any traditional milling and cutting method. however, laser cutting acrylic also poses potential hazards and safety risks. today we are focusing on the safety precautions and importance of laser cutting acrylic.

safety considerations are crucial when laser cutting acrylic. lack of safety measures will lead to multiple hazards such as health hazards, inhalation difficulties, eye injuries, skin irritation and sensitization, etc.

to avoid any unwanted experiences, follow these rules and make sure security features are enabled.

✔ proper ventilation is very important when working. smoke and gas will be generated during work. direct inhalation can cause serious health problems within days.

✔ a complete ppe suit can protect you from many long-term physical illnesses caused by exposure to laser beams. a suitable ppe suit includes an organic vapor cartridge and protective goggles to protect against possible eye damage caused by inhalation of fumes and laser radiation.

✔ ensure regular maintenance to maximize efficiency and performance. this also avoids any potential machine failures or accidents.

✔ emphasis on operator training and education. operators have the appropriate knowledge and expertise to protect the machine from any potential harm.

✔ practice and ensure compliance with regulatory requirements provided by the legal department.

nowadays, safety considerations have become very important and important due to the dangerous accidents that can occur. therefore, eastlaser recommends prioritizing safety measures, putting physical and financial safety first.

chemicals released during laser cutting

laser cutting uses high-voltage electricity to generate high temperatures, and the concentrated laser beam evaporates the material according to a predetermined path through the cnc software system, thereby forming the corresponding object shape.

throughout the processing process, some chemicals and by-products are produced as waste. here, we briefly look at the chemicals produced when laser cutting acrylic.

methyl methacrylate (mma)

the properties of methyl methacrylate and the health effects of exposure to this chemical are given below.

• methyl methacrylate is a colorless liquid with a sweet taste

• commonly used in acrylic plastics, adhesives, coatings and resin production

• skin contact may cause irritation, redness and dermatitis in those with sensitive skin

• even short-term exposure to concentrated mma can cause respiratory tract

• mma is also considered a potential carcinogen

now, it is necessary to learn and follow the exposure limits and regulations for laser cutting acrylics.

osha and acgih have established exposure limits and guidelines for mma to protect workers from a variety of health effects. osha's permissible exposure limit (pel) for mma is 100 ppm. the acgih threshold value (tlv) for mma is 50 ppm, which is an 8-hour twa.

formaldehyde

understanding the health hazards and carcinogenicity of formaldehyde will definitely help you stay safe. it is a colorless gas with a unique odor. the health hazards that may easily result may be,

• inhalation of gas can cause eye irritation. additionally, the nose, throat, and respiratory tract are common hazards of exposure

• repeated and long-term exposure to formaldehyde can lead to serious illnesses such as asthma and bronchitis, as well as allergic reactions

• the international agency for research on cancer (iarc) and the national toxicology program (ntp) classify formaldehyde as a known human carcinogen

to reduce the hazards caused by this chemical, osha and acgih have developed regulatory guidance.

osha's permissible formaldehyde exposure limit (pel) is 0.75 ppm, and acgih's formaldehyde threshold value (tlv) is 0.3 ppm (8-hour twa). osha also sets a short-term exposure limit (stel) for formaldehyde of 2 ppm. understanding regulatory guidelines for all operators is critical.

hydrogen cyanide (hcn)

this is a highly toxic element found in the production of materials containing coatings and additives. certain coated acrylic products can generate hcn. when cutting acrylic, the high temperature of the laser produces decomposition products such as cyanide.

this chemical element is highly hazardous to health. therefore, safety measures for acrylic laser cutting are a must.

inhaling hydrogen cyanide vapor can cause symptoms such as headache, dizziness, nausea, vomiting, difficulty breathing, and even loss of consciousness and death in severe cases. to minimize the possibility of any health problems, make sure to take the following steps:

appropriate ventilation systems and personal protective equipment (ppe), monitor performance and provide workers with adequate knowledge training.

health risks associated with acrylic fumes

ignoring the importance of safety precautions and failing to comply may result in serious bodily injury. prolonged exposure to hcn may cause death.

respiratory effect

• irritation and discomfort: exposure to fumes and gases and inhalation of irritants such as methyl methacrylate and formaldehyde can cause acute respiratory irritation.

• long-term health effects: long-term exposure to acrylic fumes can cause respiratory diseases such as bronchitis, asthma and chronic obstructive pulmonary disease (copd).

skin and eye irritation

• contact dermatitis: exposure to acrylic fumes can cause contact dermatitis. symptoms of contact dermatitis may include redness, itching, swelling, and blistering of the skin.

• eye irritation and damage: continued exposure to laser radiation can cause eye irritation and damage.

safety precautions for laser cutting acrylic

safety precautions are essential to reduce the likelihood of accidents when laser cutting acrylics. follow safety measures and ensure a safe working environment. some important safety measures are,

✔ make sure the cutting area is well ventilated to remove fumes and gases.

✔ install smoke extraction equipment or local exhaust ventilation.

✔ provide operators and workers with appropriate personal protective equipment.

✔ ensure workers wear respirators with organic vapor canisters to avoid direct inhalation of fumes and gases.

✔ please wear goggles and protective gloves when working.

✔ ensure regular inspection and maintenancelaser acrylic cutting machine.

✔ train operators and workers.

✔ follow the instructions provided by the manufacturer.

regulatory compliance and standards

regulations and compliance guidelines are in place to ensure the health and safety of workers and workers cutting acrylics. these standards are developed and approved by the occupational safety and health administration (osha), the national institute for occupational safety and health (niosh), and the international organization for standardization (iso).

osha regulations are as follows:

⇲ hazard communication standard (hcs).

⇲ respiratory protection standards.

⇲ personal protective equipment (ppe).

⇲ ventilation standards.

niosh has also developed some standard guidance regarding exposure to methyl methacrylate and formaldehyde for workers involved in laser cutting acrylics.

there are also iso standards to follow.

best practices for safe laser cutting operations

to ensure a safer laser cutting operation, operators and owners must follow all of the safety precautions and regulations we discuss. given below are some strategies for ensuring worker health and safety.

operator training and education

provide workers with comprehensive training on laser cutting acrylic, including setup, shutdown and operation. make sure they have emergency response training.

maintain equipment regularly

perform routine checks on machines and parameters. inspect components such as laser sources, optics, cooling systems, and safety interlocks to identify and address any signs of wear, damage, or failure.

air quality monitoring and testing

please check ventilation regularly and install necessary equipment to ensure appropriate environment and air quality.