Laser -cut polycarbonate: Is it safe?

laser cutting polycarbonate: is it safe?

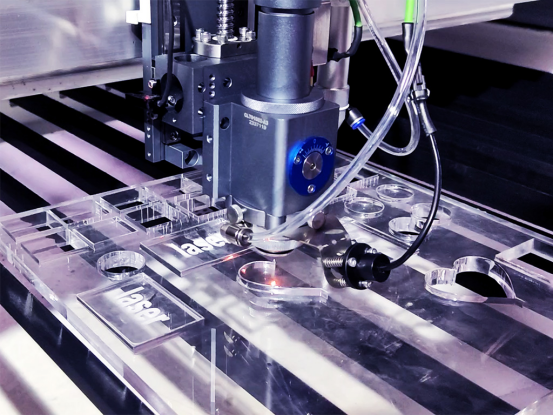

laser cutting technology makes cutting methods and precision more advanced than ever before. cutting is performed using a high-temperature concentrated laser beam. this technology is welcomed by almost every industry. the versatility of machines makes laser cutting more popular and better.

it features the ability to be shaped, carved or engraved using a variety of materials. but plastics in particular require more attention when making projects. yes, laser cutting polycarbonate is possible. you just need to know how to find the best solution for your project and properly secure the machine with the exact parameters.

today, we’ll discuss the versatility of laser cutting technology and how to use it most effectively. we will also analyze whether laser cutting polycarbonate is possible and what to do if so. let’s take a closer look at the mastery of making cutting tools.

what is laser cutting?

unlike traditional cutting and sawing methods, laser cutting uses high-temperature laser beam cutting tools to provide the most precise and efficient manufacturing results. the laser is typically focused and controlled via a cnc engraving machine.

there are two common types of lasers used for this job.

1. carbon dioxide (co2) laser

2. neodymium-doped yttrium aluminum garnet (nd: yag) laser.

this co2 laser is suitable for cutting non-metals such as wood, acrylic and fabric. nd:yag lasers, on the other hand, are used to cut metal and are capable of higher power output.

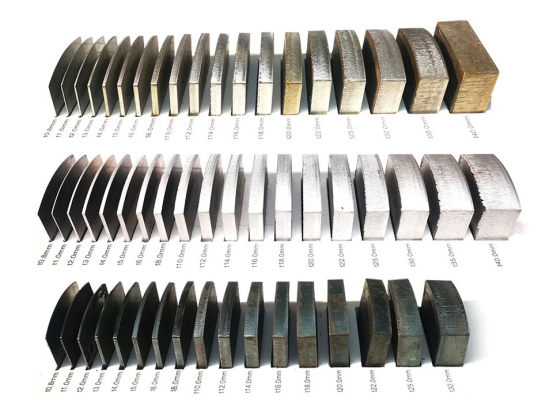

laser cutting is suitable for a variety of materials (metallic and non-metallic). currently, laser cutting can be used to cut, engrave or shape steel, aluminum, copper, wood, acrylic, plastic, leather, fabric, rubber and more.

is laser cutting polycarbonate safe?

use caution when cutting polycarbonate with a laser, as many plastics are not suitable for heat cutting. it is important to know the type of plastic you are cutting.

thickness and material density also affect cutting. lasers are not recommended for cutting all plastics. specifically, polycarbonate cuts poorly and often discolors and catches fire. typically, this material comes in flake form. for some specific reasons, laser cutting polycarbonate is not recommended for all uses.

therefore, using a laser for cutting polycarbonate is considered a poor choice due to its low efficiency on polycarbonate. but if necessary and the thickness is good, laser cutting polycarbonate is also feasible. let’s take a look at what difficulties you may face when laser cutting polycarbonate.

challenges of laser cutting polycarbonate

polycarbonate is generally not suitable for laser cutting. but as long as you follow precautions and the right steps, you can get the job done. but first, let’s take a look at the various challenges faced when laser cutting.

✔ generation of harmful smoke: high-power laser beams can produce toxic gases such as carbon monoxide and hydrogen cyanide. if ventilation is poor, serious health problems can result.

✔ material sensitivity to heat: polycarbonate is heat sensitive. excessive heat may cause the material to melt, burn, or create an undesirable finish.

✔ thermal stress and warpage possible: thermal stress is common when the laser beam overheats. this often results in discoloration and deformation of the material. it also affects the dimensional accuracy and fit of the final product.

✔ difficulty getting clean edges: getting clean, smooth edges can be a challenge when laser cutting polycarbonate. initially, the edges melt easily and tend to regain their shape. at the same time, the edges lose smoothness and shape.

✔ impact of additives and coatings: polycarbonate sheets containing additives and coatings present additional challenges. these additives and coatings create additional toxic gases and by-products when the material is heated.

additionally, the risk of surface damage, complexity of parameter optimization, and regulatory compliance and safety standards are some of the factors that present additional challenges.

the best way to cut polycarbonate

unlike laser cutting, polycarbonate has more efficient cutting methods. the best way to cut polycarbonate depends on several factors including thickness, required accuracy, and more. we’ve collected a few methods that are considered the most effective for cutting polycarbonate. let us find out what works best for you.

a. cnc tools

b. cnc engraving machine

c.table saw

d. jigsaw puzzle

e. scoring and capturing methods and

f. water jet cutting

they have proven useful to a certain extent, with fewer challenges and greater accuracy.

safety precautions

plastic materials are not environmentally friendly materials for our environment. however, its versatile composition makes it useful in many industries. cutting polycarbonate using laser cutting technology requires special safety precautions.

safety precautions need to be actively improved. here are some key safety considerations,

✔ proper ventilation is necessary to remove toxic gases and contaminants. use an exhaust system to effectively remove smoke.

✔ use only suitable equipment to maximize the smoothness and accuracy of your shapes.

✔ try to use polycarbonate sheets made specifically for laser cutting. if there are additives or coatings on the board, take necessary measures.

✔ wear appropriate personal protective equipment while working. make sure your personal protective equipment includes gloves, masks and gowns.

✔ fire safety is very important when laser cutting polycarbonate. keep a fire extinguisher nearby. keep away from flammable items.

✔ dispose of plastic waste properly.

tips for efficiently cutting polycarbonate

cutting polycarbonate can be difficult in certain work environments. however, a few tips may come in handy. try it for better results.

1. choose the right tools

choose the appropriate cutting tool based on the thickness of the board. use a table saw for thin boards and a jigsaw for curved or irregular cuts.

2. use proper cutting techniques

secure the boards to the bed properly to avoid chipping or cracking. when using a table saw, use clamps to secure the board. using a jigsaw? move it slowly and steadily.

3. optimize cutting parameters

adjust cutting speed, feed rate and blade speed according to thickness. experiment with different settings to find the best balance.

4. minimize heat build-up

avoid using sharp tools that cause excessive friction. this will reduce overheating issues. apply cutting lubricant or coolant for more effective results.

5. protective measures

wear appropriate personal protective equipment and use a dust mask.

6. clean up

remove debris and waste immediately. use sandpaper to smooth the edges so they are smooth and clean.

how to clean discolored polycarbonate after laser cutting

laser cutting polycarbonate often results in discoloration. failure to follow proper usage instructions can cause this discoloration problem!

now, what do you do once your product changes color? we provide you with some ideas that may improve your final results. you can follow these ideas step by step to get rid of this unwanted situation.

⇲ let the material cool

⇲ gently remove surface debris

⇲ prepare cleaning solution

⇲ apply cleaning solution

⇲ rinse thoroughly

⇲ polish with polishing agent

⇲ check and repeat

you can apply additional protectant to prevent future discoloration.

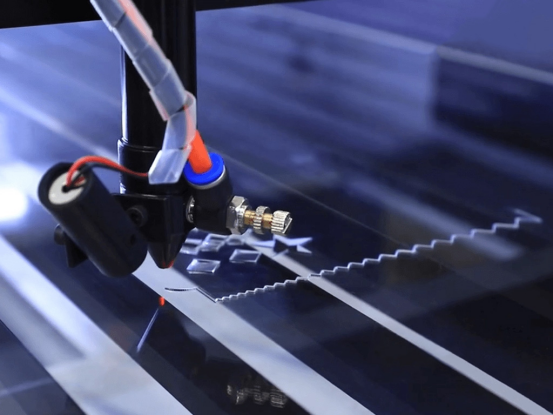

fiber laser cutting polycarbonate

fiber laser cutting is more popular among consumers for cutting polycarbonate. the right polycarbonate sheet ensures efficient cutting results. proper parameter settings also help avoid overheating and prepare for smooth cutting action.

follow the heat precautions given at the top of the article and you're all set.

post-processing is also an important task, ultimately achieving correct production. please follow safety precautions when laser cutting polycarbonate.

laser cutting polycarbonate vs acrylic

polycarbonate and acrylic are two different materials. both create contrast in terms of applying similar cutting methods. let’s take a look at the similarities and differences between laser cutting polycarbonate and acrylic.

laser cutting polycarbonate | laser cutting acrylic |

polycarbonate is a thermoplastic polymer known for its strength, durability and impact resistance. it is transparent, lightweight and shatterproof, so it is often used as a replacement for glass. | acrylic, also known as pmma (polymethyl methacrylate) or plexiglas, is a clear thermoplastic similar to glass but is lighter and more impact-resistant. acrylic is often used as a cheap alternative to glass in a variety of applications. |

polycarbonate absorbs fiber laser wavelengths and is therefore suitable for fiber laser cutting. however, care must be taken to avoid excessive heat buildup and potential thermal damage to the material. | acrylic resin is transparent to the co2 laser wavelength, making it ideal for cutting. compared to co2 lasers, sr aom can provide superior processing results in the processing of thin film materials in some automotive, electronics, lighting and packaging industries. co2 lasers are commonly used to cut acrylic because they produce clean, precise cuts with minimal heat-affected zones. |

when cutting polycarbonate with a laser, heat build-up must be controlled to prevent the material from melting or scorching. fiber lasers are commonly used to cut polycarbonate, and proper parameter optimization is critical to achieving clean, precise cuts. | acrylic cuts are clean and efficient, and the co2 laser is great for cutting the material without generating too much heat. co2 lasers have high precision and can produce complex patterns with smooth polished edges. |

laser cutting polycarbonate can sometimes cause rough or melted edges due to heat buildup during the cutting process. appropriate parameter optimization and post-processing may be required to obtain smooth, clean edges. | co2 laser cutting of acrylic produces clean, polished edges, resulting in a high-quality finish with minimal post-processing. acrylic is ideal for applications where optical clarity and edge quality are critical. |

polycarbonate is commonly used in applications that require impact resistance and durability, such as safety guards, shields, and machine guards. laser cutting polycarbonate is suitable for creating custom shapes and designs in these applications. | acrylic is widely used in signage, displays, lighting and architectural applications because of its high transparency, versatility and ease of manufacture. laser cut acrylic can be used to precisely cut intricate designs and lettering in these applications. |