What is the price of rust removal laser?

how much does rust removal laser cost?

laser rust removal is a modern laser cleaning machine that effectively removes rust and corrosion from metal surfaces using a high-intensity laser beam. it provides a very accurate and environmentally friendly solution compared to other methods. the price of a rust removal laser depends on its functionality and power, ranging from approximately $10,000 for entry-level systems to over $100,000 for high-power systems.

in this article, we’ll take a closer look at what rust removal lasers are, how they work, and the different prices one might pay. we’ll reflect on some of the advantages of these machines, factors that may affect cost, and share some thoughts on finding a more affordable model. by the time you read to the end, you’ll be completely sure whether buying a rust removal laser is worth the investment.

what is rust removal laser?

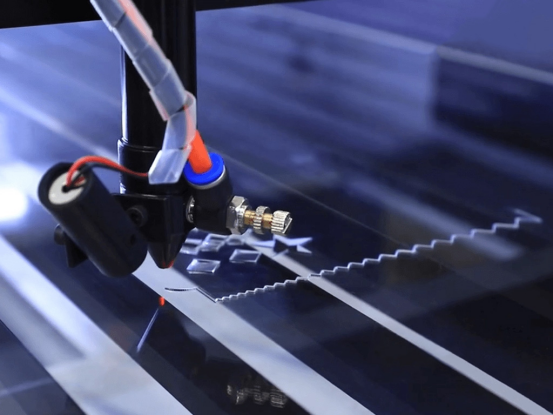

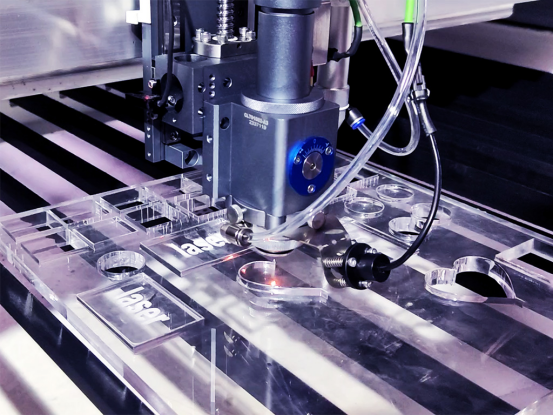

rust removal lasers use high-intensity laser beams to remove rust and corrosion from metal surfaces. unlike traditional rust removal methods that use chemicals or abrasive materials, lasers use concentrated light energy to remove rust. when the laser hits the rust, the high heat instantly evaporates the rust layer, leaving the clean metal underneath. the process is very accurate, fast and does not damage the substrate.

laser rust removal technology is widely used in the automotive, aerospace and manufacturing industries, which have high requirements for cleanliness and precision. laser rust removal is very simple to operate and is usually handheld or preset to automatic mode. unlike using chemicals, laser rust removal creates no waste. because lasers only target rust, laser rust removal is safe for the most delicate parts and intricate surfaces. overall, rust removal lasers can restore the original condition of metal surfaces in an environmentally friendly and time-saving way.

how does rust removal laser work?

rust removal lasers work by focusing a powerful laser beam onto the rusted surface. a very powerful laser beam with high intensity generates heat to evaporate the rust layer, thereby removing it without damaging the metal underneath. the process is very precise: it targets only rust and is therefore perfect even for the most delicate and detailed parts.

when a laser shines on rust, the energy heats the rust particles until they evaporate. the process requires no chemicals or abrasives, making it both safe and environmentally friendly. the laser can adjust to different types and thicknesses of rust, giving it the flexibility to work on a variety of surfaces and materials.

laser rust removers are typically portable or stationary and come with adjustable settings for power, focus, and intensity. operators can easily control these machines, minimizing the risk of damaging metal surfaces. because it creates no waste or residue, this method is clean and usually requires minimal cleanup. efficient, precise and effective, rust removal lasers are a quick way to repair metal parts.

how much does rust removal laser cost?

when considering a rust removal laser, it’s important to understand the associated costs. prices may vary based on features, power, and brand. lower-priced lasers may be suitable for smaller projects, while higher-end lasers are better suited for industrial use.

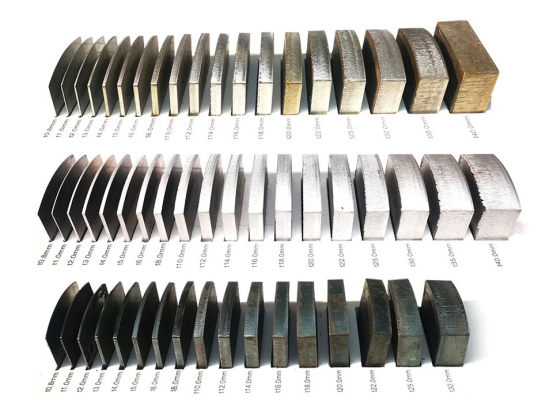

entry level (low power: 50-200w)

these small laser rust removers are best for small delicate jobs or light rust removal. they can cost between $5,600 and $9,800. they are compact enough for use in small workshops or for low intensity use. these machines are great for hobbyists and small businesses.

mid-range (medium power: 300-500w)

more powerful mid-range machines are effective for general rust removal tasks on larger surfaces. they are suitable for most industrial applications and range in price from $10,800 to $16,000. these lasers offer a good balance between performance and cost, making them a popular choice for many businesses. they can handle medium workloads efficiently.

high-end (high power: 1000-3000w)

high-power laser rust removal machines are designed for large-scale industrial applications. these powerful systems range in price from $3,800 to over $18,000. they are efficient and remove quickly, making them ideal for harsh environments. these machines are typically used in large manufacturing or repair facilities.

customizable or robotic systems available

some high-end systems offer robotic capabilities or specialized configurations for production line integration. these setups can cost more than $36,000, depending on specifications and degree of automation. they provide advanced solutions for high-volume rust removal tasks. these machines increase productivity by automating repetitive processes.

factors affecting the price of rust removal laser

several factors can affect the cost of a rust removal laser, including machine specifications and brand reputation. here’s a breakdown of the main factors that influence price.

laser power

the power of a laser is one of the main factors in its price. lower power lasers, such as 50-watt models, are generally less expensive and suitable for lighter applications. high-power lasers, such as 1000-watt machines, are more expensive but remove rust faster and more thoroughly. for industrial applications, high-power lasers are more common, which increases the overall price.

machine portability

portable rust removal lasers typically cost less than larger, stationary lasers. portable lasers are designed for small tasks and personal use, so they cost less. however, stationary or industrial-grade machines are suitable for heavy-duty applications and are more expensive. these large lasers are designed to handle large-scale rust removal projects and therefore cost more but are more efficient.

laser technology type

fiber lasers are a popular choice for rust removal and generally cost more due to their efficiency and durability. different types of laser technology have unique advantages, which affect their cost. fiber lasers offer faster processing speeds and longer lifetimes, making them more expensive upfront but valuable over the long term.

brand reputation and warranty

generally speaking, price tends to match reputation. brands with proven reliability in the market usually have higher prices but offer longer warranties and provide better customer support. likewise, all machines that come with extensive warranties may fall into the high-end category but are guaranteed to be covered in case of repairs or any kind of support.

maintenance and operating costs

the cost of maintaining a laser rust remover will also affect its overall price. machines with simpler designs are less expensive to maintain, while more complex machines require more frequent repairs and therefore increase operating costs. higher-end models may have automated features that minimize operating costs, but these features may increase upfront costs.

additional accessories and features

some lasers come with additional accessories, such as dust collection systems, safety devices, or advanced software. these features may increase the cost of the machine but increase value and efficiency. machines with adjustable laser settings or a more comprehensive control panel may also be more expensive.

benefits of laser rust removal

laser rust removal offers many advantages over traditional methods. it's efficient and environmentally friendly. here are some of the key benefits of using laser technology for rust removal.

• effective rust removal: lasers remove rust quickly and thoroughly. they can target specific areas without damaging surrounding materials.

• precision and control: laser systems are highly precise and operators can easily control the intensity and focus of the laser.

• minimal surface damage: unlike abrasive methods, lasers do not scratch or damage underlying surfaces. this maintains the integrity of the metal.

• environmentally friendly: laser rust removal does not require harmful chemicals. this is a safer option for both the user and the environment.

• reduced waste: lasers produce minimal debris compared to traditional methods. this reduces cleanup and waste disposal.

• versatility: lasers can work on a variety of surfaces, including steel, aluminum and other metals. they are suitable for a wide range of applications.

• affordable: while the initial cost may be high, lasers can reduce long-term maintenance expenses. its efficiency saves labor and materials.

• improved safety: laser systems are often equipped with safety features. they minimize the risk of accidents and injuries during operation.

• fast operation: laser rust removal is faster than many traditional methods. this increases productivity and reduces downtime

is it worth investing in a rust removal laser?

for many businesses, purchasing a laser rust remover is basically a great idea. the initial investment may seem ridiculously high, but when compared to the benefits it brings, it’s worth it. these machines remove rust faster and more efficiently, thus also saving time and thus labor costs.

rust removal lasers also minimize material damage. they target rust precisely without damaging the surface underneath. this means fewer repairs and replacements are needed, which can be expensive. additionally, laser technology is environmentally friendly, reducing the use of harmful chemicals.

additionally, investing in a rust removal laser can increase productivity. businesses can complete work faster, thereby increasing production. over time, this efficiency can lead to significant savings. overall, while the investment is significant, the long-term benefits make it a valuable addition to any operation involving rust removal.

portable handheld laser rust removal machine

faqs about rust removal laser machines and pricing

have questions about rust removal laser machines? this faq section provides clear answers to frequently asked questions. read on to learn more about these machines and their pricing.

what is a rust removal laser machine?

laser rust remover is mainly used to remove rust and corrosion from metal surfaces. the device's laser beam focuses and vaporizes rust without touching the underlying material. the method is effective and environmentally friendly. this machine is widely used in many industries.

how much does a rust removal laser cost?

different powerful features increase the price of rust removal laser machines. entry-level models range in price from $5,600 to $9,800. mid-range machines generally range in price from $10,800 to $16,000. high-end robotic systems can cost as much as $36,000 (taking into account specifications).

is the laser rust removal machine easy to use?

yes, most laser rust removers are easy to use. they usually come with intuitive controls and clear instructions. operators can learn to use them effectively with some training. safety features are also included to ensure safe operation.

what are the benefits of using laser rust removal?

laser rust removal offers several advantages. this is a precise method that minimizes damage to the surface underneath the rust. it is also fast and can effectively cover large areas. additionally, this method is environmentally friendly and produces minimal waste.

how long is the service life of a laser rust remover?

the use and maintenance of the rust removal laser machine determines its service life. if properly maintained, most machines can easily last more than ten years. this can usually be ensured by more frequent maintenance. additionally, investing in high-quality machines from reputed brands guarantees durability.