What is the speed and thickness of the fiber laser cutting metal?

at what speed and thickness can a fiber laser cut metal?

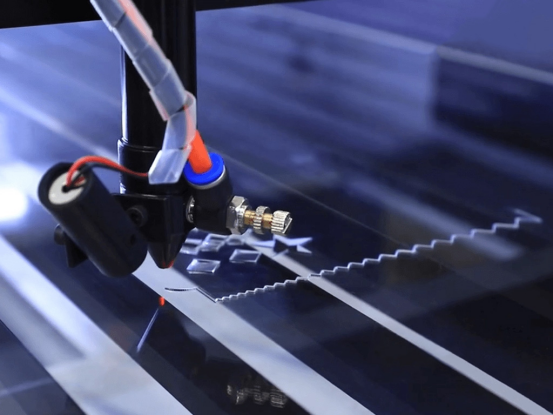

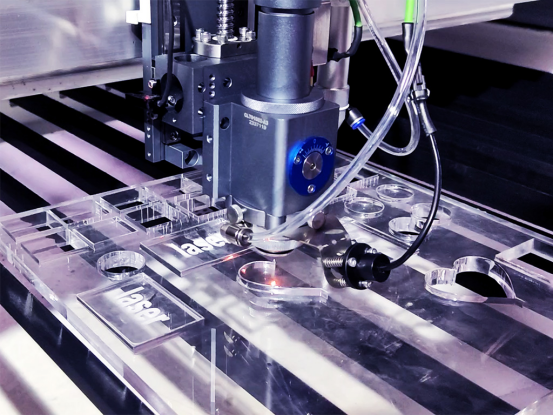

in the early days of automated metal processing, business owners often tended to purchase a entry-level cnc plasma cutting table or waterjet cutter for rough cuts of thick metal, and a fine cnc plasma cutter for precise cuts of thin metal. with the demand for manufacturing safety and environmental protection in metal processing, yag and co2 laser cutting machines laser cutting machines began to enter the market, taking metal cutting quality to the next level. moreover, laser is more environmentally friendly and safer than plasma and water jet, and requires no consumables. however, both yag and co2 lasers have their own limitations, such as high investment costs, limited cutting thickness, and even not as fast as plasma. at this time, the fiber laser cutting machine launched by a new type of laser metal cutting system is a professional metal cutting machine. whether it is quality, speed or thickness, with the change of laser power, it has reached unprecedented heights, high precision, features and advantages such as high quality, fast speed, low cost, ease of use, and full automation make it a unicorn in the field of pipe and plate processing.

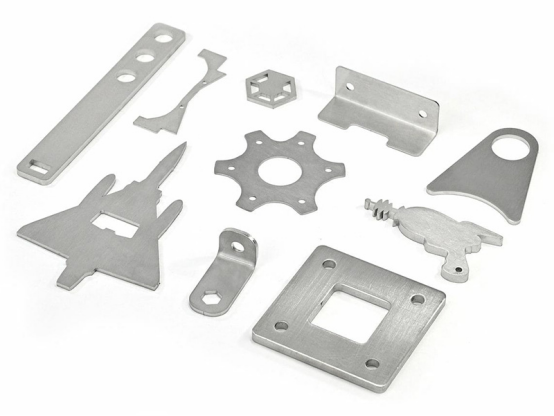

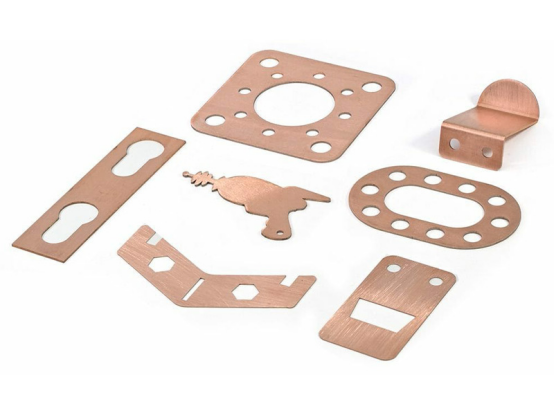

fiber laser cutting machine is a new high-precision metal cutting system that uses a cnc controller to drive a laser head to cut metal with design layout files, thereby automating metal manufacturing in small businesses and industrial manufacturing. it can cut easily from 1mm stainless steel to over 100mm carbon steel and even highly reflective metals like brass, copper, aluminum, gold and silver, using different working gases including air, nitrogen and oxygen to create smooth silhouette. whether it's sheet metal, pipe or special profiles, fiber laser machines cut precise and clean shapes.

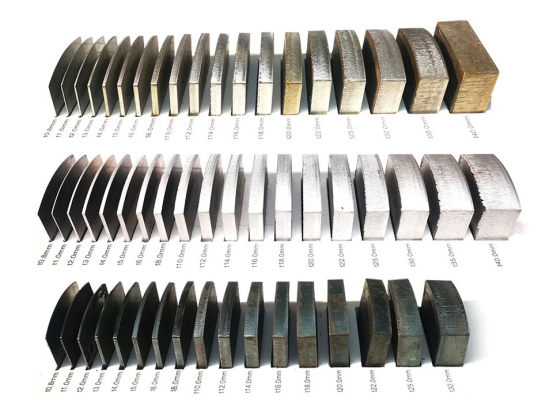

with such a powerful cutting tool, have you ever wondered how thick a metal it can cut? what are the limitations of cutting speed? how do various laser powers perform in terms of cutting metal thickness and speed? below is a practical guide for beginners and experts, allowing us to analyze in detail various metal materials, working gases, laser power, cutting thickness and speed.

fiber laser cutting carbon steel thickness and speed and power charts

carbon steel is an iron-carbon alloy with a carbon content between 0.02% and 2%.

carbon steel that fiber lasers can cut includes low carbon steel (low carbon steel), medium carbon steel (m2 steel) and high carbon steel (tool steel).

fiber laser cutting machine can easily cut carbon steel with thickness from 1 mm to more than 200 mm, speed from 0.12 m/min to 100 m/min, optional power from 1000w and up to 60000w, working gas options include air, oxygen, nitrogen and mixed gases.

low/medium power (1000w - 4000w) carbon steel cutting parameters

material | gas | thickness(mm) | speed (m/min) | ||||

1000W | 1500W | 2000W | 3000W | 4000W | |||

carbon steel | air transport | 1 | 12.0-15.0 | 15.0-20.0 | 25.0-30.0 | 28.0-35.0 | 30.0-38.0 |

2 | 3.5-4.5 | 5.0-8.0 | 7.0-10.0 | 8.0-12.0 | 10.0-16.0 | ||

3 | 1.5-3.0 | 2.0-4.0 | 2.5-4.5 | 3.0-5.0 | |||

4 | 1.5-2.3 | 2.5-3.5 | |||||

5 | 1.0-2.2 | ||||||

nitrogen | 1 | 15.0-20.0 | 18.0-25.0 | 22.0-30.0 | 25.0-38.0 | 30.0-44.0 | |

oxygen | 2 | 3.5-5.0 | 3.8-5.0 | 5.0-6.0 | 5.5-7.0 | 5.5-7.7 | |

3 | 2.5-3.5 | 2.8-3.8 | 3.5-4.3 | 3.6-5.0 | 3.7-5.5 | ||

4 | 2.0-3.3 | 2.3-3.5 | 2.8-4.0 | 3.0-4.5 | 3.5-4.6 | ||

5 | 1.4-2.0 | 1.6-2.5 | 2.5-3.0 | 2.5-3.3 | 2.5-4.0 | ||

6 | 1.2-1.6 | 1.4-1.8 | 2.2-2.5 | 2.3-2.8 | 2.5-3.5 | ||

8 | 0.8-1.1 | 0.9-1.3 | 1.3-1.8 | 1.8-2.2 | 2.0-2.8 | ||

10 | 0.6-0.9 | 0.8-1.2 | 1.2-1.5 | 1.2-1.6 | 1.2-2.2 | ||

12 | 0.4-0.7 | 0.7-1.0 | 0.8-1.0 | 1.0-1.3 | 1.0-1.7 | ||

16 | 0.5-0.7 | 0.6-0.8 | 0.6-0.9 | 0.7-1.0 | |||

20 | 0.5-0.8 | 0.6-0.9 | |||||

22 | 0.5-0.8 | ||||||

low/medium power (1000w - 4000w) carbon steel cutting parameters

material | gas | thickness(mm) | speed (m/min) | ||||

1000W | 1500W | 2000W | 3000W | 4000W | |||

carbon steel | air transport | 1 | 12.0-15.0 | 15.0-20.0 | 25.0-30.0 | 28.0-35.0 | 30.0-38.0 |

2 | 3.5-4.5 | 5.0-8.0 | 7.0-10.0 | 8.0-12.0 | 10.0-16.0 | ||

3 | 1.5-3.0 | 2.0-4.0 | 2.5-4.5 | 3.0-5.0 | |||

4 | 1.5-2.3 | 2.5-3.5 | |||||

5 | 1.0-2.2 | ||||||

nitrogen | 1 | 15.0-20.0 | 18.0-25.0 | 22.0-30.0 | 25.0-38.0 | 30.0-44.0 | |

oxygen | 2 | 3.5-5.0 | 3.8-5.0 | 5.0-6.0 | 5.5-7.0 | 5.5-7.7 | |

3 | 2.5-3.5 | 2.8-3.8 | 3.5-4.3 | 3.6-5.0 | 3.7-5.5 | ||

4 | 2.0-3.3 | 2.3-3.5 | 2.8-4.0 | 3.0-4.5 | 3.5-4.6 | ||

5 | 1.4-2.0 | 1.6-2.5 | 2.5-3.0 | 2.5-3.3 | 2.5-4.0 | ||

6 | 1.2-1.6 | 1.4-1.8 | 2.2-2.5 | 2.3-2.8 | 2.5-3.5 | ||

8 | 0.8-1.1 | 0.9-1.3 | 1.3-1.8 | 1.8-2.2 | 2.0-2.8 | ||

10 | 0.6-0.9 | 0.8-1.2 | 1.2-1.5 | 1.2-1.6 | 1.2-2.2 | ||

12 | 0.4-0.7 | 0.7-1.0 | 0.8-1.0 | 1.0-1.3 | 1.0-1.7 | ||

16 | 0.5-0.7 | 0.6-0.8 | 0.6-0.9 | 0.7-1.0 | |||

20 | 0.5-0.8 | 0.6-0.9 | |||||

22 | 0.5-0.8 | ||||||

ultra-high power (40000w) carbon steel cutting parameters

material | thickness(mm) | speed (m/min) | power (watts) | working gas |

carbon steel | 5 | 28.0-32.0 | 40000 | nitrogen/air |

6 | 25.0-28.0 | |||

8 | 22.0-24.0 | |||

10 | 16.0-20.0 | |||

12 | 14.0-17.0 | |||

14 | 11.0-13.0 | |||

16 | 8.0-9.5 | |||

18 | 8.0-8.5 | |||

20 | 7.0-8.0 | |||

25 | 5.0-5.5 | |||

30 | 3.0-4.0 | |||

40 | 1.5-2.0 | |||

50 | 0.7-1.0 | |||

10 | 2.0-2.3 | 6000 | o₂(positive focus) | |

12 | 1.8-2.0 | 7,500 | ||

14 | 1.6-1.8 | 8,500 | ||

16 | 1.6-1.8 | 9,500 | ||

20 | 1.5-1.6 | 12000 | ||

22 | 1.4-1.5 | 18000 | ||

25 | 1.2-1.4 | 18000 | ||

30 | 1.2-1.3 | 18000 | ||

40 | 0.9-1.1 | 26000 | ||

40 (not q235) | 0.3-0.6 | 20000 | ||

50 (not q235) | 0.3-0.5 | 25000 | ||

50 | 0.8-1.0 | 40000 | ||

60 | 0.6-0.9 | |||

70 | 0.5-0.7 | |||

80 | 0.4-0.6 | |||

90 | 0.3-0.4 | |||

100 | 0.2-0.3 | |||

12 | 3.2-3.5 | 20000 | o₂ (negative focus) | |

14 | 3.0-3.2 | |||

16 | 3.0-3.1 | |||

20 | 2.8-3.2 | |||

25 | 2.4-2.8 | 40000 | ||

30 | 2.4-2.6 | |||

35 | 2.3-2.6 | |||

40 | 2.0-2.3 | |||

50 | 1.2-1.6 | |||

60 | 1.0-1.3 | |||

70 | 0.6-0.8 |

ultra-high power (60000w) carbon steel cutting parameters

material | thickness(mm) | speed (m/min) | power (watts) | working gas |

carbon steel | 16 | 13.0-14.0 | 60000 | mixed gas - (n₂&o₂)/air |

18 | 11.0-12.0 | |||

20 | 9.0-10.0 | |||

25 | 6.5-7.5 | |||

30 | 4.5-5.5 | |||

35 | 3.5-4.4 | |||

40 | 2.8-3.4 | |||

45 | 2.0-2.5 | |||

50 | 1.5-2.0 | |||

60 | 1.0-1.4 | |||

16 | 1.6-1.8 | 12000 | o₂(positive focus) | |

18 | 1.6-1.7 | |||

20 | 1.5-1.6 | |||

25 | 1.2-1.4 | 20000 | ||

30 | 1.2-1.3 | |||

35 | 1.1-1.2 | |||

40 | 0.9-1.1 | 25000 | ||

45 | 0.8-1.0 | |||

50 | 0.75-0.9 | 30000 | ||

60 | 0.7-0.8 | 50000 | ||

70 | 0.7-0.8 | 60000 | ||

80 | 0.6-0.7 | |||

100 | 0.5-0.6 | |||

160 | 0.15-0.25 | |||

200 | 0.15-0.2 | |||

20 | 2.4-3.0 | 15000 | o₂ (negative focus) | |

25 | 2.2-2.6 | 30000 | ||

30 | 2.0-2.4 | |||

35 | 2.0-2.2 | 35000 | ||

40 | 1.6-2.0 | |||

45 | 1.4-1.8 | 40000 | ||

50 | 1.2-1.6 | |||

60 | 1.0-1.3 | 60000 | ||

70 | 1.0-1.2 | |||

80 | 0.8-1.0 | |||

100 | 0.5-0.65 |

fiber laser cutting stainless steel thickness and speed and power chart

stainless steel refers to alloy steel with high chromium content (generally 12%~30%), which is passivity, corrosion-resistant, rust-free in the atmosphere and corrosive media such as acids, alkalis, and salts. it contains nickel, molybdenum, and vanadium. , manganese, tungsten and other elements alloy steel, also known as acid-resistant steel, white iron, water copper iron.

astm grade and model stainless steel fiber lasers can cut 201, 202, 205, 301, 302, 302b, 302cu, 303, 304, 304l, 304n, 305, 308, 309, 310, 314, 316, 316l, 316n, 317, 31 7l, 321, 329, 330, 347, 384, 403, 405, 409, 410, 414, 416, 420, 422, 429, 430, 430f, 431, 434, 436, 439, 440 (440a, 44b, 0c) , 440, 444, 446, 501, 502l and 904.

the fiber laser cutting machine can cut stainless steel as thin as 1 mm and as thick as 150 mm. the speed is as low as 0.05 m/min and as high as 100 m/min. the laser power range is from 1000 watts to 60000 watts. the working gas can be n₂ and air. .

low/medium power (1000w - 4000w) stainless steel cutting parameters

material | gas | thickness(mm) | speed (m/min) | ||||

1000W | 1500W | 2000W | 3000W | 4000W | |||

stainless steel | air transport | 1 | 15.0-25.0 | 18.0-30.0 | 20.0-35.0 | 32.0-40.0 | 35.0-50.0 |

2 | 4.0-7.0 | 8.0-12.0 | 10.0-15.0 | 14.0-18.0 | 16.0-23.0 | ||

3 | 2.5-3.5 | 3.0-4.0 | 5.0-7.0 | 8.0-12.0 | 8.0-14.0 | ||

4 | 0.6-1.0 | 2.0-3.0 | 3.5-4.5 | 5.5-8.0 | 6.0-10.0 | ||

5 | 0.5-0.8 | 1.2-1.8 | 1.8-2.5 | 3.5-5.0 | 4.5-6.0 | ||

6 | 0.5-0.8 | 0.7-0.8 | 2.5-3.0 | 2.8-4.8 | |||

8 | 0.5 | 1.2-1.5 | 1.8-3.0 | ||||

10 | 0.8-1.2 | 0.85-1.8 | |||||

12 | 0.65-1.0 | ||||||

nitrogen | 1 | 16.5-22.0 | 20.0-26.0 | 27.5-33.0 | 31.0-38.5 | 33.0-45.0 | |

2 | 4.5-6.1 | 7.0-10.0 | 9.0-11.0 | 12.0-16.5 | 15.0-20.0 | ||

3 | 2.0-3.1 | 4.5-5.5 | 5.0-6.5 | 7.0-10.0 | 7.5-12.0 | ||

4 | 1.0-1.6 | 2.0-2.5 | 2.2-2.8 | 5.0-7.2 | 5.5-9.0 | ||

5 | 0.4-0.7 | 1.5-2.0 | 1.5-2.0 | 1.8-2.4 | 4.0-5.5 | ||

6 | 0.6-0.9 | 0.7-1.3 | 1.0-1.6 | 2.6-4.5 | |||

8 | 0.3-0.6 | 1.2-2.0 | 1.6-2.8 | ||||

10 | 0.7-1.0 | 0.7-1.6 | |||||

12 | 0.5-0.9 | ||||||

high power (6000w - 30000w) stainless steel cutting parameters

material | gas | thickness(mm) | speed (m/min) | |||||

6000W | 8000W | 12000W | 15000W | 20000W | 30000W | |||

stainless steel | air transport | 1 | 55.0-70.0 | 65.0-75.0 | 70.0-85.0 | 80.0-95.0 | 83.0-100.0 | 85.0-100.0 |

2 | 32.0-45.0 | 40.0-50.0 | 45.0-55.0 | 48.0-55.0 | 55.0-70.0 | 65.0-80.0 | ||

3 | 20.0-28.0 | 27.0-33.0 | 30.0-38.0 | 35.0-40.0 | 45.0-52.0 | 55.0-60.0 | ||

4 | 13.0-18.0 | 15.0-20.0 | 25.0-30.0 | 25.0-29.0 | 30.0-40.0 | 38.0-45.0 | ||

5 | 10.0-15.0 | 12.0-16.0 | 16.0-19.0 | 18.0-23.0 | 23.0-28.0 | 27.0-33.0 | ||

6 | 7.0-10.0 | 9.0-11.0 | 13.0-17.0 | 14.0-19.0 | 18.0-23.0 | 24.0-28.0 | ||

8 | 4.5-6.0 | 5.5-6.0 | 9.0-11.0 | 8.0-12.0 | 14.0-16.0 | 20.0-24.0 | ||

10 | 2.0-3.0 | 4.0-4.5 | 6.5-8.0 | 6.8-8.5 | 9.0-12.0 | 15.0-20.0 | ||

12 | 1.4-1.8 | 2.5-3.5 | 5.5-6.0 | 5.5-6.5 | 8.0-10.0 | 12.5-15.0 | ||

16 | 0.8-1.0 | 1.3-2.0 | 2.2-2.8 | 4.5-5.5 | 5.5-6.5 | 8.0-9.0 | ||

20 | 0.5 | 0.7-1.0 | 1.5-2.0 | 1.9-2.1 | 2.7-3.2 | 4.5-5.5 | ||

25 | 0.5-0.8 | 0.8-1.2 | 1.2-1.4 | 1.8-2.5 | 2.5-3.0 | |||

30 | 0.25-0.4 | 0.5-0.8 | 0.8-1.0 | 1.4-1.6 | 1.5-2.2 | |||

40 | 0.4-0.5 | 0.5-0.8 | 0.8-1.0 | |||||

50 | 0.17-0.3 | 0..3-0.4 | 0.3-0.45 | |||||

60 | 0.14-0.18 | 0.16-0.2 | ||||||

70 | 0.1-0.13 | 0.1-0.15 | ||||||

80 | 0.05 | |||||||

nitrogen | 1 | 50.0-65.0 | 63.0-66.0 | 70.0-80.0 | 75.0-90.0 | 80.0-100.0 | 82.0-100.0 | |

2 | 30.0-40.0 | 40.0-44.0 | 44.0-48.0 | 46.0-50.0 | 50.0-60.0 | 63.0-75.0 | ||

3 | 18.0-25.0 | 25.0-28.0 | 28.0-35.0 | 30.0-38.0 | 35.0-45.0 | 52.0-58.0 | ||

4 | 10.0-15.5 | 15.0-18.0 | 20.0-26.0 | 22.0-28.0 | 30.0-32.0 | 35.0-43.0 | ||

5 | 8.0-13.5 | 12.0-14.0 | 15.0-20.0 | 16.0-22.0 | 24.0-28.0 | 25.0-30.0 | ||

6 | 6.0-9.0 | 9.0-9.5 | 11.0-13.0 | 12.0-15.0 | 20.0-25.0 | 22.0-25.0 | ||

8 | 4.0-5.5 | 5.0-5.3 | 7.0-7.5 | 7.5-8.5 | 14.0-17.0 | 18.0-22.0 | ||

10 | 1.8-2.8 | 3.8-4.0 | 5.0-5.5 | 5.5-6.5 | 10.0-13.0 | 14.0-18.0 | ||

12 | 1.2-1.6 | 2.5-2.7 | 3.0-3.5 | 3.3-4.0 | 9.0-10.0 | 12.0-14.0 | ||

14 | 0.8-1.2 | 1.8-1.9 | 2.3-2.8 | 2.5-3.0 | 7.0-8.5 | 8.0-10.0 | ||

16 | 0.6-0.9 | 1.3-1.5 | 2.1-2.5 | 2.3-2.8 | 5.0-6.0 | 7.0-8.0 | ||

20 | 0.7-0.8 | 1.4-1.7 | 1.5-1.9 | 2.5-3.0 | 4.0-5.0 | |||

25 | 0.5-0.6 | 0.7-1.0 | 0.9-1.2 | 1.4-1.8 | 2.0-2.5 | |||

30 | 0.5-0.7 | 0.6-0.8 | 0.9-1.2 | 1.2-2.0 | ||||

35 | 0.4-0.5 | 0.5 | 0.55-0.8 | 0.7-1.0 | ||||

40 | 0.3 | 0.4 | 0.4-0.5 | 0.6-0.8 | ||||

50 | 0.2 | 0.25 | 0.3-0.35 | 0.3-0.4 | ||||

60 | 0.15 | 0.15-0.2 | 0.15-0.25 | |||||

70 | 0.1-0.13 | 0.12-0.15 | ||||||

80 | 0.06-0.08 | 0.08-0.1 | ||||||

90 | 0.05-0.06 | 0.5-0.08 | ||||||

100 | 0.03-0.04 | 0.04-0.05 | ||||||

ultra-high power (40000w) stainless steel cutting parameters

material | thickness(mm) | speed (m/min) | power (watts) | working gas |

stainless steel | 5 | 25.0-30.0 | 40000 | nitrogen |

6 | 22.0-25.0 | |||

8 | 20.0-23.0 | |||

10 | 16.0-21.0 | |||

12 | 12.0-14.0 | |||

14 | 10.0-12.0 | |||

16 | 9.0-11.0 | |||

18 | 8.0-9.5 | |||

20 | 7.0-8.5 | |||

25 | 4.5-5.5 | |||

30 | 3.0-4.0 | |||

40 | 1.5-2.0 | |||

50 | 0.5-0.8 | |||

60 | 0.4-0.6 | |||

70 | 0.2-0.3 | |||

80 | 0.2-0.25 | |||

90 | 0.14-0.18 | |||

100 | 0.08-0.12 | |||

5 | 30.0-34.0 | 40000 | air transport | |

6 | 25.0-30.0 | |||

8 | 22.0-25.0 | |||

10 | 17.0-23.0 | |||

12 | 13.0-16.0 | |||

14 | 12.0-14.0 | |||

16 | 9.0-11.5 | |||

18 | 8.0-10.0 | |||

20 | 7.0-9.0 | |||

25 | 5.0-5.5 | |||

30 | 3.5-4.5 | |||

40 | 1.7-2.2 | |||

50 | 0.7-1.0 | |||

60 | 0.4-0.6 | |||

70 | 0.3-0.4 | |||

80 | 0.25-0.3 | |||

90 | 0.2-0.25 | |||

100 | 0.15-0.2 |

ultra-high power (60000w) stainless steel cutting parameters

material | thickness(mm) | speed (m/min) | power (watts) | working gas |

stainless steel | 16 | 13.0-14.0 | 60000 | nitrogen |

18 | 11.0-12.0 | |||

20 | 9.0-10.0 | |||

25 | 6.5-7.5 | |||

30 | 5.0-6.0 | |||

35 | 3.5-4.5 | |||

40 | 3.0-3.5 | |||

50 | 1.8-2.2 | |||

60 | 1.3-1.6 | |||

70 | 1.0-1.2 | |||

80 | 0.6-0.8 | |||

90 | 0.4-0.6 | |||

90 (modulation) | 0.2-0.25 | |||

100 | 0.3-0.5 | |||

100 (modulation) | 0.15-0.2 | |||

120 | 0.1-0.15 | |||

16 | 13-14.5 | 60000 | air transport | |

18 | 11-12.5 | |||

20 | 9-10.5 | |||

25 | 7.0-7.8 | |||

30 | 5.0-6.0 | |||

35 | 4.0-4.5 | |||

40 | 3.2-4.0 | |||

50 | 3.0-3.5 | |||

60 | 1.8-2.2 | |||

70 | 1.0-1.2 | |||

80 | 0.7-0.8 | |||

90 | 0.5-0.6 | |||

100 | 0.4-0.5 | |||

120 | 0.25-0.35 | |||

150 | 0.15-0.2 | |||

200 (modulation) | 0.05-0.1 |

fiber laser cutting aluminum thickness & speed & power chart

aluminum is the most abundant silver-white light metal, soft and malleable.

lasers can easily cut foils, plates, strips, tubes, rods and profiles made of aluminum and aluminum alloys.

the fiber laser cutting system is ideal for cutting rolled aluminum, cast aluminum, pure aluminum alloys, aluminum alloys containing copper, manganese, silicon, magnesium and zinc up to 100 mm thick with a maximum speed of 70 m/min and a laser power option of 1000w to 40000w and n₂ working gas.

low/medium power (1000w - 4000w) aluminum cutting parameters

material | gas | thickness(mm) | speed (m/min) | ||||

1000W | 1500W | 2000W | 3000W | 4000W | |||

aluminum plate | nitrogen | 1 | 10.0-13.0 | 15.0-27.5 | 22.0-31.0 | 25.0-30.0 | 28.0-32.0 |

2 | 2.0-4.5 | 7.0-8.6 | 10.0-13.2 | 15.0-18.0 | 16.0-20.0 | ||

3 | 0.6-1.3 | 2.5-4.0 | 5.0-6.6 | 7.0-8.0 | 10.0-12.0 | ||

4 | 1.0-1.6 | 1.5-2.2 | 5.0-6.0 | 6.0-7.0 | |||

5 | 0.6-0.9 | 1.0-1.3 | 2.5-3.0 | 4.0-5.0 | |||

6 | 0.6-0.9 | 1.5-2.0 | 2.5-3.0 | ||||

8 | 0.4-0.7 | 0.5-0.8 | 1.0-1.3 | ||||

10 | 0.3-0.4 | 0.8-1.0 | |||||

12 | 0.6-0.8 | ||||||

14 | 0.3-0.5 | ||||||

high power (6000w - 30000w) aluminum cutting parameters

material | gas | thickness(mm) | speed (m/min) | |||||

6000W | 8000W | 12000W | 15000W | 20000W | 30000W | |||

aluminum plate | nitrogen | 1 | 35.0-45.0 | 40.0-50.0 | 45.0-55.0 | 50.0-60.0 | 55.0-65.0 | 60.0-70.0 |

2 | 20.0-25.0 | 25.0-30.0 | 30.0-35.0 | 35.0-38.0 | 40.0-45.0 | 45.0-50.0 | ||

3 | 14.0-16.0 | 15.0-23.0 | 20.0-25.0 | 25.0-30.0 | 30.0-35.0 | 38.0-45.0 | ||

4 | 8.0-10.0 | 12.0-16.0 | 18.0-20.0 | 20.0-23.0 | 25.0-30.0 | 28.0-35.0 | ||

5 | 5.0-7.0 | 7.0-10 | 14.0-16.0 | 15.0-18.0 | 18.0-20.0 | 20.0-25.0 | ||

6 | 3.5-4.0 | 5.0-7.0 | 10.0-12.0 | 12.0-14.0 | 16.0-18.0 | 18.0-22.0 | ||

8 | 1.5-2.0 | 2.5-4.0 | 6.0-8.0 | 8.0-10.0 | 10.0-13.0 | 14.0-18.0 | ||

10 | 1.0-1.2 | 2.0-2.5 | 4.0-6.0 | 5.0-7.0 | 9.5-10.0 | 12.0-15.0 | ||

12 | 0.6-0.7 | 1.6-2.0 | 2.0-3.0 | 2.5-3.5 | 5.0-6.0 | 10.0-12.0 | ||

14 | 0.4-0.6 | 0.8-1.2 | 1.5-2.5 | 2.0-3.0 | 4.5-5.0 | 8.0-10.0 | ||

16 | 0.3-0.4 | 0.8-1.0 | 1.3-2.0 | 1.5-2.5 | 3.0-4.0 | 6.0-8.0 | ||

20 | 0.5-0.7 | 0.8-1.2 | 0.8-1.2 | 1.6-2.0 | 2.0-3.0 | |||

25 | 0.4-0.5 | 0.5-0.7 | 0.5-0.7 | 1.0-1.2 | 1.5-2.0 | |||

30 | 0.4-0.5 | 0.45-0.6 | 0.8-1.0 | 1.0-1.2 | ||||

35 | 0.3-0.35 | 0.45-0.55 | 0.7-0.9 | 0.8-1.0 | ||||

40 | 0.25-0.3 | 0.28-0.33 | 0.4-0.7 | 0.5-0.8 | ||||

50 | 0.15-0.2 | 0.2-0.25 | 0.3-0.5 | 0.4-0.6 | ||||

60 | 0.2 | 0.2-0.3 | 0.25-0.35 | |||||

70 | 0.08-0.13 | 0.12-0.15 | ||||||

80 | 0.08-0.1 | |||||||

ultra-high power (40000w) aluminum cutting parameters

material | thickness(mm) | speed (m/min) | power (watts) | working gas |

aluminum plate | 5 | 25.0-30.0 | 40000 | nitrogen |

6 | 20.0-25.0 | |||

8 | 18.0-22.0 | |||

10 | 14.0-17.0 | |||

12 | 11.0-13.0 | |||

14 | 9.0-11.0 | |||

16 | 7.0-9.0 | |||

18 | 5.0-7.0 | |||

20 | 4.0-5.0 | |||

25 | 3.0-3.5 | |||

30 | 2.0-3.0 | |||

40 | 1.0-1.5 | |||

50 | 0.4-0.6 | |||

60 | 0.2-0.3 | |||

70 | 0.2-0.25 | |||

80 | 0.15-0.2 | |||

90 | 0.12-0.15 | |||

100 | 0.08-0.1 |

fiber laser cutting brass and copper thickness and speed and power charts

copper is a soft and malleable metal with excellent electrical and thermal conductivity, ductility and corrosion resistance. brass is an alloy of copper and zinc that has high mechanical properties and wear resistance.

lasers can easily cut brass to create precision instruments, ship parts, electronic components, bullets, musical instruments, ornaments, coins and molds.

in addition to ordinary copper and brass, fiber lasers can cut aluminum bronze, manganese bronze, aluminum brass, gun metal (tin-zinc bronze), white copper and nickel-copper alloy (monel) with thicknesses from 1 mm to 80 mm. speeds from 0.4 m/min to 65 m/min, laser powers as low as 1000w and as high as 40000w, using nitrogen to cut brass and oxygen to cut copper.

low/medium power (1000w - 4000w) brass cutting parameters

material | gas | thickness(mm) | speed (m/min) | ||||

1000W | 1500W | 2000W | 3000W | 4000W | |||

brass | nitrogen | 1 | 14.0-20.0 | 15.0-22.0 | 20.0-27.0 | 20.0-28.0 | 25.0-30.0 |

2 | 3.0-4.5 | 4.0-7.2 | 7.7-8.8 | 7.0-13.2 | 12.0-15.0 | ||

3 | 1.0-1.2 | 1.1-1.5 | 3.0-4.5 | 5.0-7.2 | 5.5-7.7 | ||

4 | 1.0-1.2 | 1.3-1.8 | 2.5-3.0 | 3.5-5.5 | |||

5 | 0.6-0.9 | 0.8-0.9 | 1.6-2.0 | 2.0-3.5 | |||

6 | 0.4-0.6 | 0.8-1.2 | 1.4-2.2 | ||||

8 | 0.3-0.4 | 0.8-1.0 | |||||

10 | 0.4-0.6 | ||||||

high power (6000w - 30000w) brass cutting parameters

material | gas | thickness(mm) | speed (m/min) | |||||

6000W | 8000W | 12000W | 15000W | 20000W | 30000W | |||

brass | nitrogen | 1 | 30.0-40.0 | 35.0-45.0 | 38.0-50.0 | 40.0-55.0 | 45.0-60.0 | 55.0-65.0 |

2 | 15.0-18.0 | 25.0-27.0 | 30.0-35.0 | 32.0-37.0 | 35.0-40.0 | 38.0-45.0 | ||

3 | 12.0-14.0 | 15.0-18.0 | 18.0-22.0 | 20.0-24.0 | 25.0-28.0 | 28.0-33.0 | ||

4 | 8.0-10.0 | 10.0-12.0 | 15.0-18.0 | 16.0-19.0 | 19.0-22.0 | 22.0-26.0 | ||

5 | 5.0-5.5 | 7.0-9.0 | 12.0-15.0 | 13.0-16.0 | 17.0-19.0 | 18.5-22.0 | ||

6 | 3.2-3.8 | 6.0-6.5 | 7.0-10.0 | 9.0-11.0 | 12.0-15.0 | 15.0-18.0 | ||

8 | 1.5-1.8 | 2.5-3.0 | 5.5-6.5 | 6.0-8.0 | 8.0-10.0 | 10.0-15.0 | ||

10 | 0.8-1.0 | 1.0-1.5 | 3.5-4.7 | 5.0-6.0 | 7.0-8.0 | 8.0-10.0 | ||

12 | 0.6-0.7 | 0.8-1.2 | 1.8-2.0 | 2.0-2.2 | 2.5-3.5 | 5.0-8.0 | ||

15 | 0.6-0.7 | 1.0-1.2 | 1.3-1.4 | 1.8-2.0 | 2.5-4.5 | |||

18 | 0.5-0.7 | 0.8-1.2 | 0.8-1.3 | 1.3-1.8 | ||||

20 | 0.3-0.5 | 0.6-0.7 | 0.8-1.0 | 1.0-1.2 | ||||

25 | 0.4-0.6 | 0.7-0.9 | 0.8-1.0 | |||||

30 | 0.3-0.5 | 0.5-0.7 | 0.6-0.8 | |||||

40 | 0.4-0.5 | 0.5-0.65 | ||||||

50 | 0.4-0.5 | |||||||

ultra high power (40000w) brass and copper cutting parameters

material | thickness(mm) | speed (m/min) | power (watts) | working gas |

brass | 5 | 25.0-30.0 | 40000 | nitrogen |

6 | 20.0-25.0 | |||

8 | 18.0-22.0 | |||

10 | 10.0-14.0 | |||

12 | 8.0-11.0 | |||

14 | 6.0-8.0 | |||

16 | 5.0-7.0 | |||

18 | 4.0-5.0 | |||

20 | 3.0-4.0 | |||

25 | 2.5-3.0 | |||

30 | 2.0-2.5 | |||

copper | 3 | 20.0-25.0 | 40000 | oxygen |

4 | 18.0-20.0 | |||

5 | 15.0-18.0 | |||

6 | 10.0-15.0 | |||

8 | 6.0-10.0 | |||

10 | 2.0-3.5 | |||

12 | 2.0-2.5 | |||

14 | 1.5-2.0 | |||

16 | 1.0-1.5 | |||

20 | 0.6-1.0 |

in short, fiber lasers can cut metal as thin as 1 mm and as thick as 100 mm or more at speeds as low as 0.05 m/min and as high as 100 m/min or more, with laser powers ranging from 1000w to 60000w. different power and working gas, cutting thickness and speed will be different.

things to consider

fiber laser cutting machines are powerful and can easily and accurately cut common metal materials, even some highly reflective metals such as aluminum, copper, and brass. however, cutting precious metals like gold and silver is a bit troublesome. this requires finding the best power options and working gases, and adjusting to set the correct laser cutting parameters to get the job done smoothly and avoid unnecessary waste.

if you want to use gold and silver to cut exquisite decorations, jewelry, crafts and gifts as well as some precision parts and accessories, please feel free to ask eastlaser's technical staff to provide solutions for your business and budget.