8:30 AM - 6:00 PM

8:30 AM - 6:00 PM

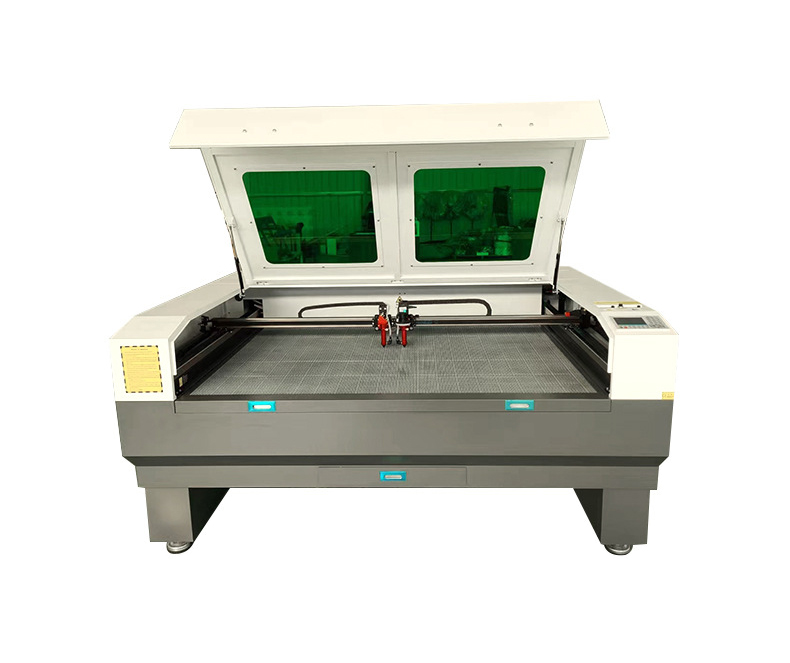

Brand -Eastlaser Model -East1610 Standards -Meeting CE standards in terms of quality and safety Warranty -the entire machine 1 year limited warranty

brand - eastlaser

model - east1610

standards - meet ce standards in terms of quality and safety

warranty - 1 year limited warranty on entire machine

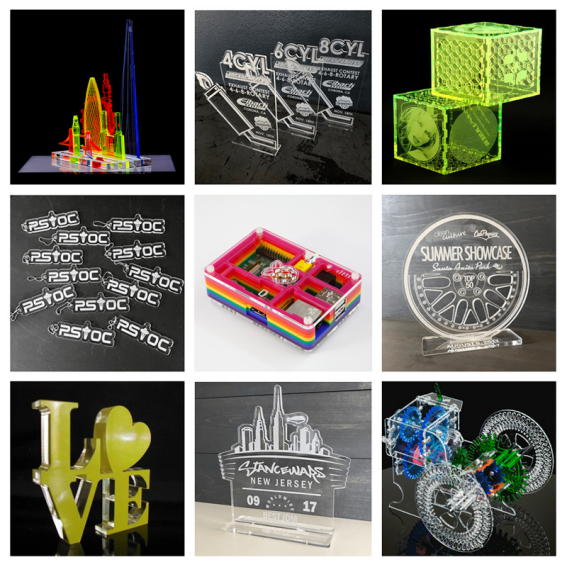

do you have plans for a diy acrylic laser cutter kit or need to buy an affordable acrylic laser cutter? check out the new 2025 laser acrylic cutting machine buying guide below, we will provide you with the best acrylic and plastic laser cutting machines in 2025 and provide customized laser acrylic cutting services to suit your 2d/3d laser cutting acrylic projects, ideas and plans.

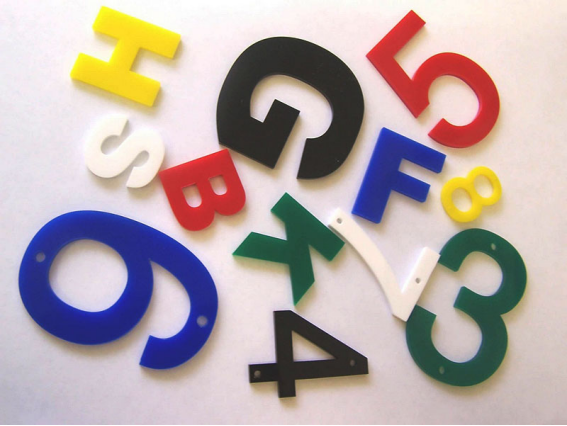

acrylic is a clear plastic homopolymer often known by the trade name "plexiglass." acrylic is very similar to polycarbonate in that it is suitable for use as an impact-resistant replacement for glass. there are clear, white, black, bulletproof, mirror, matte, anti-glare, sandblasted (frosted) or uv filtered acrylic sheets in the world. when you are doing acrylic engraving and cutting in your studio or home shop, you should purchase a laser cutting machine with a co2 laser source. so, let’s find out what is an acrylic laser cutting machine?

laser plastic cutting machine is a kind of laser cutting machine for polyethylene terephthalate (pet or pete), high density polyethylene (hdpe), polyvinyl chloride (pvc or vinyl), low density polyethylene (ldpe), cnc laser cutting machine for polypropylene (pp), polystyrene (ps or styrofoam) and other plastics.

plastic laser cutting machines are mainly used to cut various polymer materials such as engineering plastics, foam plastics, and general plastics. the laser plastic cutting machine has accurate cutting, fast speed, simple operation, personalized processing process and precision, simulation display of the laser head running trajectory, multi-path optimization function, and adopts a professional automatic typesetting system to ensure maximum saving of materials and cost.

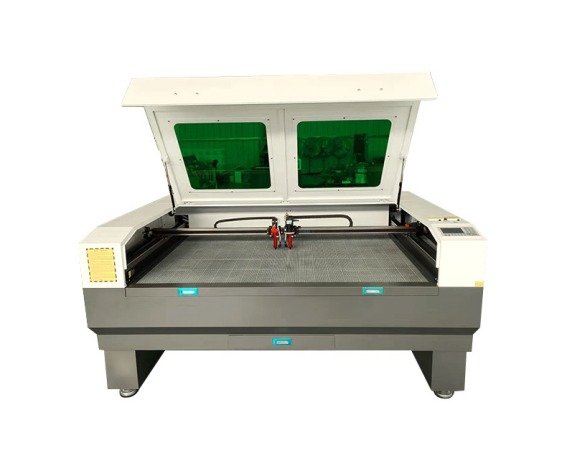

1. square linear guide rails are installed on the xy axis to ensure stable and accurate work.

2. the acrylic laser cutting machine is equipped with a square tube frame, and the body strength is more than 40% higher than the iron plate structure. this design prevents vibration, resonance and deformation of the laser machine during long-term operation.

3. adopt new high-efficiency laser tube. the laser beam is more stable than traditional types. more than 10,000 hours of use.

4. a red dot position system is added to the standard configuration, which facilitates simple and precise working position.

5. the humanized and modern appearance shows the humanized concept and makes operation and maintenance quite easy.

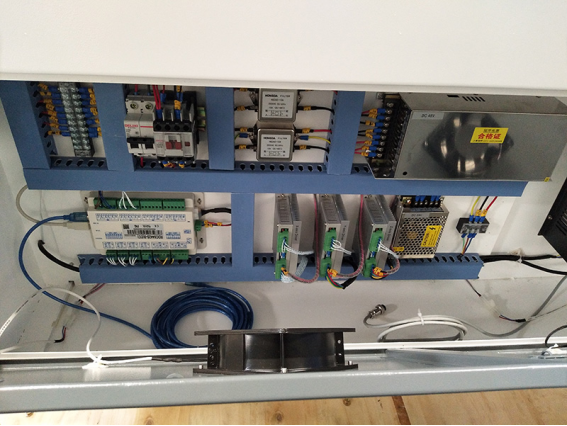

6. the advanced dsp control system, combined with a professional motion control chip, has continuous high-speed curve cutting and shortest path selection functions, which greatly improves your work efficiency.

7. usb offline control system makes operation more convenient and faster.

8. for thicker materials and tall objects, an automatic lifting platform can be selected.

product model | EAST1610 |

effective format | 1600x1000mm |

laser power | 80w/100w/130w/150w (standard 80w) |

laser type | co2 sealed glass laser |

work platform | blade platform (honeycomb platform optional) |

cold way | water cooling (water pump or chiller) |

engraving scan speed | 0-3000mm/min |

cutting speed | 0-3600mm/min |

cutting thickness | 0-15mm (depending on the material) acrylic can be cut within 15mm thickness |

power supply | 220V 50Hz |

laser energy control | 1-100% software setting |

minimal formed text | chinese characters 1.8x1.8mm, english 10x1.0mm |

maximum scanning accuracy | ±0.1mm |

repeat positioning accuracy | +0.1mm |

support graphic formats | DST、PLT、BMP、DXF、Al |

support software | CORELDRAW、PHOTOSHOP、AUTOCAD等 |

software language | simplified chinese, traditional chinese, english |

working environment | temperature 0~45℃ humidity 5%~95% |

overall dimensions | 2220*2000*1080mm |

weight | 700KG |

the acrylic laser cutting system is suitable for acrylic, fabric, leather, toys, computer embroidery cutting, molds, handicrafts, bamboo, advertising and architectural decoration, packaging and printing, paper products and other industries at an affordable price.

the acrylic laser cutting system can be used to engrave and cut acrylic, color plates, abs boards, rubber, plastics, cloth toys, leather, wool, crystal, glass, ceramic tiles, jade, bamboo products, and wood products.

laser acrylic cutting machines vary in price depending on the required work size and laser tube wattage, i hope you can tell us the answers below and then we can recommend the best acrylic cutting machine to you.

1. what material do you want to engrave or cut?

2. what is the size of your engraving or cutting material? (length, width, thickness)

many friends have reported to us that cutting acrylic is troublesome and prone to problems such as uneven cutting surfaces, strong concavities and convexities, whitish cutting edges, and edge melting caused by reflection of honeycomb panels. what should we do?

compared with the usual plywood cutting, acrylic cutting does not seem to be as simple as imagined, and it is not necessary to follow the cutting parameters of wood to achieve the best results. in order to cut acrylic flat and smooth, without whitening the edges, and without reflecting light from the honeycomb panel, we made a simple analysis of this acrylic cutting test below.

1. set the power to 65%-70%.

the minimum power and maximum power are set because cutting straight lines is faster than cutting corners. we say that the faster the speed, the shallower the cut. therefore, in order to be able to cut through the sample, we usually set minimum and maximum power.

2. set the speed to 5mm/s.

we all know that the faster the speed, the higher the processing efficiency, so when cutting general materials, we will try to increase the power to increase the speed, but it is different with acrylic. if the speed is too fast, the cutting surface will be uneven and uneven. sense, so in order to cut out a smooth effect. things to remember when setting parameters: increase power, decrease speed.

3. do not blow when cutting.

when many people cut acrylic, they encounter the problem of whitening on the cut surface. this is because they use blow air when cutting, so if you want a smooth cut, turn off the blow air. be careful when cutting acrylic without blowing. since there is no strong blowing flame retardant, the material can easily catch fire during the cutting process. if a fire is found, please shut down the machine in time.

4. overhead cutting.

when cutting acrylic, if we want to avoid the edge blending problem caused by the reflection of the honeycomb board, we can solve it by overhead cutting.

in summary

to sum up, we know that when cutting 6mm acrylic, we might as well set the power to 65%-70% and the speed to 5mm/s. at the same time, choose not to blow air during the cutting process, and you can use it when appropriate. the overhead cutting method is used to solve the reflection problem of honeycomb panels; of course, but if we want to cut with a frosted effect, we only need a simple step, which is to turn on the air blowing, so that the cut acrylic will have a frosted appearance. influence.