8:30 AM - 6:00 PM

8:30 AM - 6:00 PM

Brand -Eastlaser Model -East -2000 Standards -Meeting CE standards in terms of quality and safety Warranty -the entire machine 1 year limited warranty

brand - eastlaser

model - east-2000

standards - meet ce standards in terms of quality and safety

warranty - 1 year limited warranty on entire machine

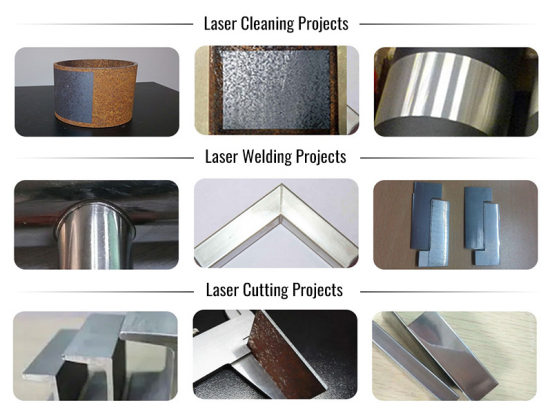

are you looking for a versatile laser machine that can weld, clean and cut? instead of choosing a single-purpose laser welding machine to join metal parts, or a single-purpose fiber laser cutting machine to cut metal sheets, tubes, and profiles, or a single-purpose laser cleaning machine to remove rust, paint, and coatings.

here is the multi-purpose all-in-one laser machine you dream of - east-2000. it can not only weld different metal plates, pipes and profiles of various types, sizes and thicknesses, but also cut stainless steel, carbon steel, copper, aluminum, titanium and some alloys can even be used to clean various substrates and materials for surface treatment.

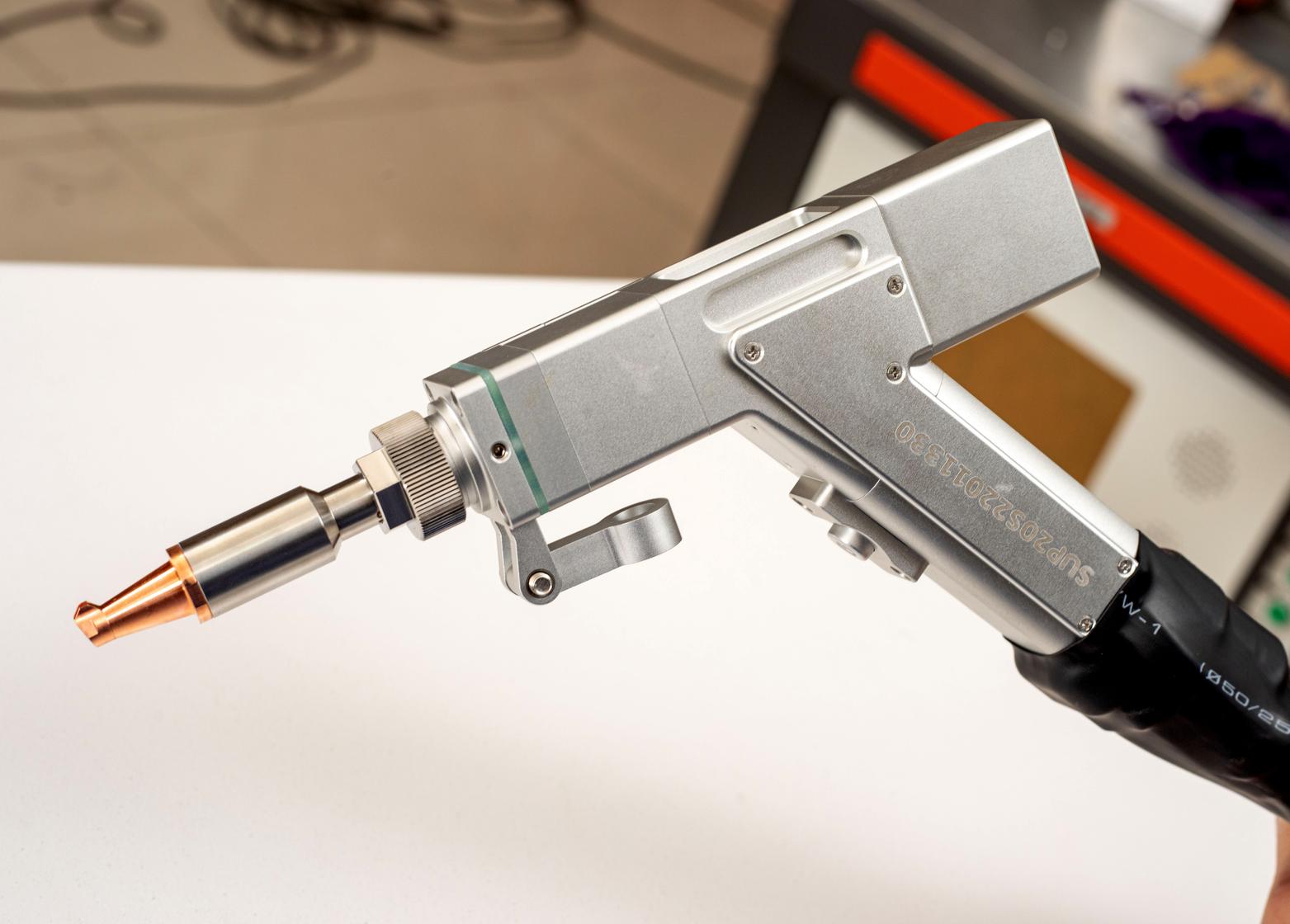

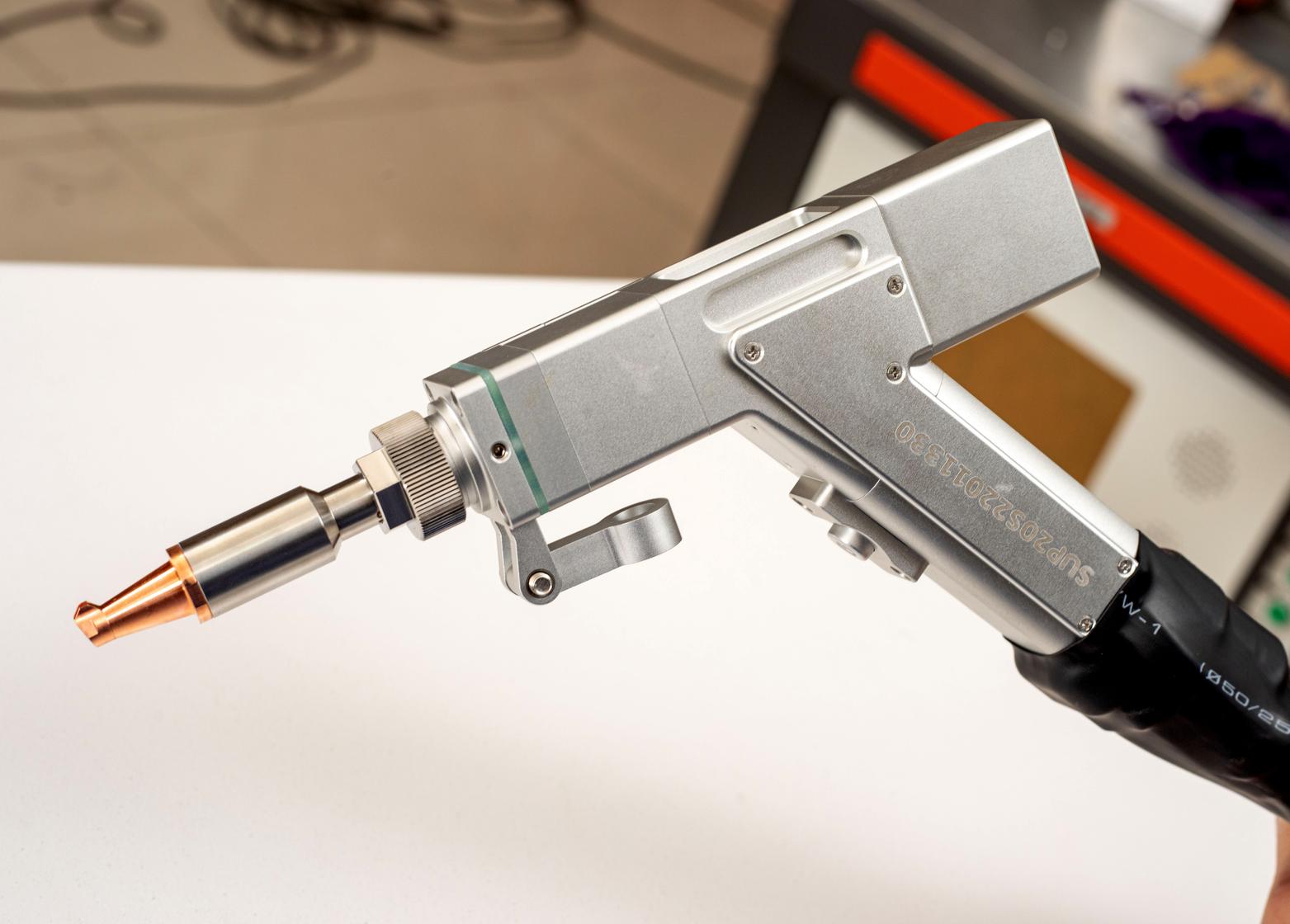

portable handheld laser welding machines are innovative tools for precession welding in a variety of industries. the handheld laser welding machine is a portable laser beam welding machine that couples a high-heat energy beam into an optical fiber, converts it into parallel light through a collimating lens, focuses it on weldable metal parts, and releases heat to melt the metal piece. connected together.

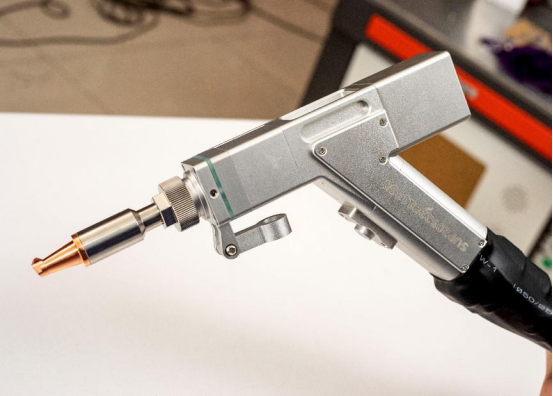

the portable laser welding machine is an easy-to-move welding machine that is used with a handheld laser welding gun to achieve the connection of indoor and outdoor metal joints. it is user-friendly and easy to use for both beginners and professionals.

achieve non-contact welding of those difficult-to-weld parts, flexible and convenient. manual laser beam welding machines can achieve spectral separation of time and energy while creating multi-beam welding, providing conditions for high-precision welding compared with traditional mig and tig welding machines, electric welding machines and more arc welding machines.

the three-in-one laser welding, cleaning and cutting machine is an all-in-one tool kit that integrates the three functions of welding, cutting and cleaning. it consists of a fiber laser generator, a handheld laser gun, a water chiller and a three-in-one control system. it is portable and convenient and easy to use.

✔available in 1000w, 1500w, 2000w, 3000w power options for various penetration depths up to 8mm.

✔ easy to move, flexible and convenient, can be welded indoors and outdoors.

✔ fast welding speed, 2-10 times faster than traditional mma, tig and mig welding machines.

✔ the weld is straight and even, smooth and clean, with deep penetration and small taper. no polishing is required, saving time and cost.

✔ strong welded metal joint, no deformation and less scars.

✔ less consumables, low energy consumption and long service life.

✔ user-friendly, easy to use, safe and environmentally friendly.

✔ limited power compared to large fixed laser welding systems.

✔ operator skills are required to avoid welding defects.

✔ ongoing repairs and maintenance may incur additional costs.

Model | EAST-1500, EAST-2000, EAST-3000 |

Laser Power | 1500W, 2000W, 3000W |

Laser WaveLength | 1080nm |

Fiber Length | Standard 10 Meters (Maximum 15 Meters) |

Operate Mode | Continuation |

Cooling Chiller | Industrial Water Chiller Inside |

Working Environment Temperature Range | 15-35 ℃ |

Humidity Range of Working Environment | < 70% No Condensation |

Weld Thickness Recommendations | 0.5 - 8mm |

Working Voltage | 220V/2P for 1500W, 2000W; 380V/3P for 3000W |

⇲ laser energy density is high, the thermal effect area is small, it is not easy to deform, and there is less or no need for subsequent processing.

⇲ integrated control cabinet with laser generator, power pack, industrial chiller, controller, powerful functions, small footprint and easy to move.

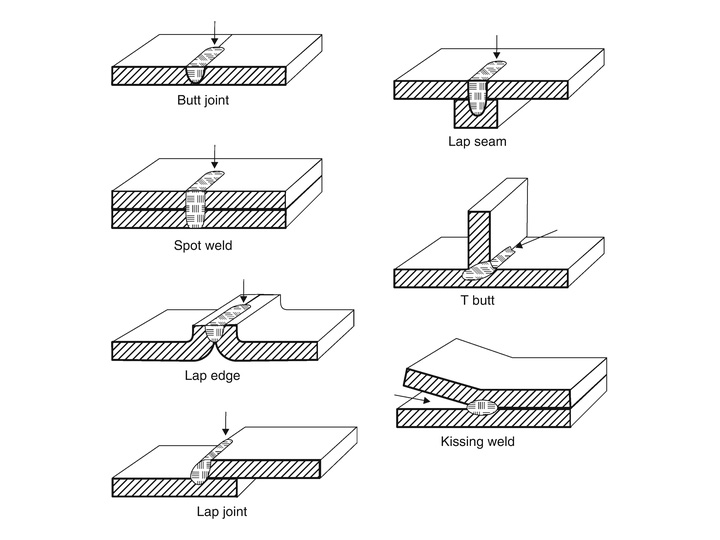

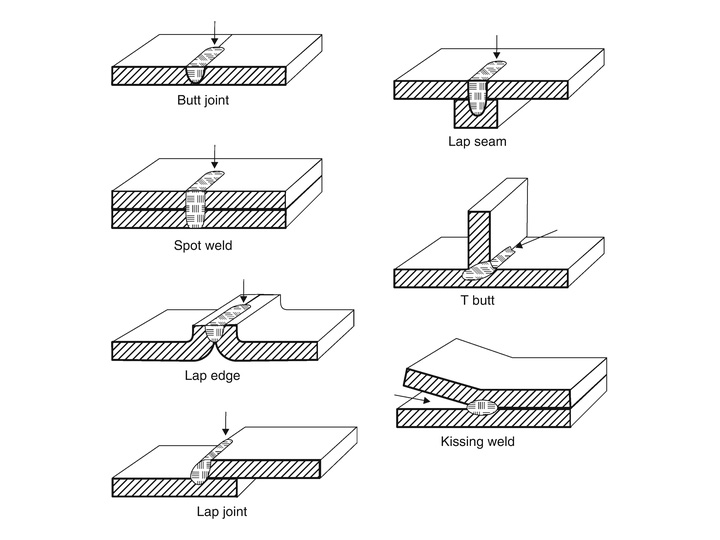

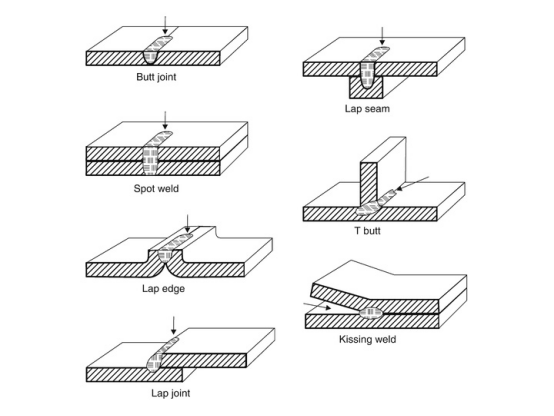

⇲easy to spot weld, stitch, nail, butt, overlap, splice, edge, stack, crimp and t-weld.

⇲ multiple detection and protection measures ensure long-term stable operation of the machine and avoid losses and injuries caused by accidents.

⇲ non-contact processing, no pressure, no noise, no pollution to the environment, and is a green processing.

⇲ high welding quality and smooth and clean appearance.

⇲ communication function monitors all data of the laser.

⇲ the welding machine comes with a special optical fiber that can weld tiny solder bumps.

⇲ high-quality fiber laser beam, high conversion efficiency, therefore high speed, high aspect ratio, high intensity.

⇲ excellent spectroscopy system minimizes energy loss and ensures that the laser energy of each fiber is almost the same.

⇲ the welding machine uses optical fiber transmission, which can realize remote welding and facilitate working with automatic welding workbench, manipulator, assembly line and other equipment. after light transmission, the light spot is more uniform and the solder joints are more beautiful.

⇲ a variety of input and output signals make it very easy to realize automated production and assembly line production of the machine.

⇲ the welding joints are pollution-free, and the strength and toughness of the welding seam are at least equal to or stronger than those of the base metal.

⇲ touch screen input and friendly human-computer interaction make setup and operation easier. the operating system is easy to learn and easy to operate.

⇲ various angle nozzles and wire feeding nozzles of various specifications are available to meet the welding needs of different projects.

the handheld laser welding gun is a portable welding machine that combines a laser generator, controller, cooling system and automatic wire feeder to perform stitching, nailing, butt jointing, lap jointing, edge, crimp and t-welding, and more many types of metal connectors. the handheld laser welding gun is flexible and convenient, and can achieve long-distance and outdoor welding. the user-friendly operating mode enables weldable parts to be in any position and at any angle, suitable for various complex metal joints.

the handheld laser beam welding gun consists of a gun body, a cooling chamber and a protective gas chamber. it is not only simple and compact in structure, easy to operate and carry anywhere, but also can be easily connected to the cooling medium source and protective gas source, so that the laser gun can be effectively cooled and the working area can also be effectively utilized. a protective gas atmosphere is formed to ensure reliable welding quality.

a dual-oscillation laser welder is a versatile welder with two oscillating axes that effectively joins materials, usually metals, through precise and controlled heating. this design enables the dual-axis laser welder to produce high-quality welds with minimal distortion and is particularly suitable for complex geometries and precision components in industries such as automotive, aerospace, shipbuilding, electronics and medical device manufacturing.

high welding quality

biaxial laser welders ensure even heating and fusion of the weld area, resulting in stronger, more reliable welds.

increase productivity

dual oscillating motion allows for faster welding speeds and reduced welding time.

versatility

dual-oscillation laser welders can be used to weld a variety of materials and joint configurations.

improved accessibility

the oscillating motion allows for better access to hard-to-reach areas, making it ideal for complex welding projects.

reduce heat input

controlled movement helps minimize heat input, reducing the risk of workpiece deformation and damage.

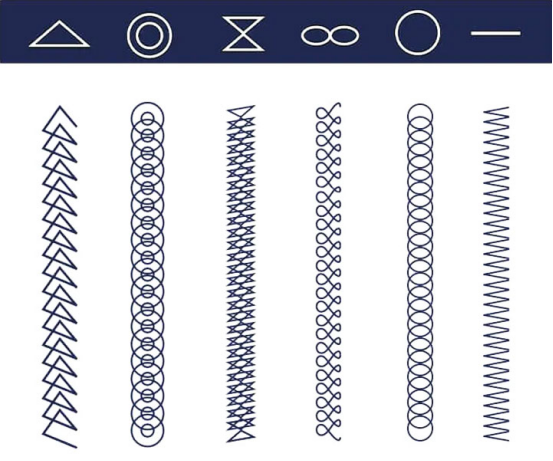

the dual-oscillation welding gun has six welding modes to choose from. different welding modes can make the welding surface more beautiful and present different welding process modes. multi-mode welding has better filling effect and stronger welding strength than single horizontal line welding.

the portable laser welder can weld stainless steel, carbon steel, brass, copper, aluminum, gold, chromium, silver, titanium, nickel, platinum, rhodium, tantalum, niobium, tungsten, molybdenum and other metals or alloys, and can also weld various different types of metal materials, including brass versus stainless steel, copper versus brass, titanium versus molybdenum, titanium versus gold, nickel versus copper, etc.

handheld laser welding machines are used in a variety of industries from home use to industrial manufacturing:

aviation - engine casings, wing gaskets, fuselage skins and ribs, wall panels, bellows.

electronic instruments - integrated circuit leads, picture tube electron guns, all-tantalum capacitors, speed control tubes, instrument hairsprings.

mechanical - precision springs, dot matrix printer parts, metal thin-walled bellows, thermocouples, electro-hydraulic servo valves.

iron and steel metallurgy - welding silicon steel sheets with a thickness of 0.2~8mm and a width of 0.5~1.8mm, high, medium and low carbon steel and stainless steel, with a welding speed of 100~1000cm/min.

automotive - roofs, bodies, side frames, chassis, transmissions, gears, ignition center shafts and dial assemblies, etc.

high-speed rail - honeycomb structure of the car body.

ships - decks, bulkheads, bulkheads, flat plate sandwich members.

medical - lithium-iodine batteries used in pacemakers and pacemakers.

food - food cans (using laser welding machine instead of traditional welding or contact high-frequency welding machine, it has the characteristics of non-toxic, fast welding speed, material saving, beautiful joints, excellent performance, etc.).

others - gas turbines, heat exchangers, dry cell zinc and copper casings, nuclear reactor parts.

mma welder (manual metal arc welder), also known as mmaw or smaw (shielded metal arc welder), has the characteristics of excessive welding spatter, low filler metal utilization, and the need for frequent slag removal and bar replacement, resulting in extremely slow speed. production efficiency is low. additionally, the greater reliance on rods requires welders with operational skills and experience.

mig welder (metal inert gas welder) is characterized by high thread volume and heat input, which makes thin metal sheets prone to deformation and burn-through, and medium-thickness metal sheets require grooves, resulting in rough welds that require subsequent polishing.

tig welder (tungsten inert gas welder) has the characteristics of shallow penetration depth and large melting width, which makes it only able to weld thin metal plates and causes large deformation. additionally, high currents can cause the tungsten electrodes to melt and evaporate, making manually filling the wires difficult and inefficient.

the handheld laser welder has the characteristics of environmental protection, pollution-free, deep penetration, high speed, smooth and clean welds, and small deformation. it reduces the subsequent grinding process and can obtain straight and uniform welds without the need for professionals.

mma, tig and mig welders require experienced welders, as well as beginners who have undergone extensive training and research, while handheld laser welders are intuitive, concise, user-friendly and easy to use, with the most commonly used parameters preset so you can customize them define settings and save what you need, and beginners can easily get started in just a few hours.

the speed of mma, tig and mig welders usually does not exceed 1 centimeter per second, while the speed of handheld laser welders can reach 2-10 centimeters per second, which is 2-10 times more efficient than traditional manual arc welders. in addition, the handheld laser welder can easily weld various types of metals, including ordinary steel (such as carbon steel, stainless steel, galvanized steel), aluminum alloy and brass, with a welding penetration depth (wpd) of up to 8mm for steel and aluminum alloy or brass up to 6mm.

compare items | arc welding machine | laser welding machine |

heat input | high | low |

workpiece deformation | big | small |

bonding strength | low | high |

follow-up processing | needs polishing | no sanding required |

welding speed | slow | 2-10 times higher |

consumable materials | many | few |

operation difficulty | complex | easy to use |

human security | not safe | safety |

environmental protection | pollute | environmental friendly |

spot width | not adjustable | adjustable |

welding quality | inferior | good |

handheld laser welding machines can be used for various welding purposes. the power and capabilities of these machines may vary. we already know that these machines range in power from 1000w to 3000w. they can also be distinguished by their abilities.

in addition to common handheld laser welders, you can also come across portable three-in-one laser machines, which are equipped with a handheld laser welding gun for joining metal parts, a handheld laser cutting gun for metal cutting, and a handheld laser cutting gun for removing metal parts. handheld laser cleaning gun for rust and paint removal.

the handheld laser welder is user-friendly with a touch screen controller that is easy to use and requires no experience. beginners can easily operate it after a few hours of learning and operating it, much easier than mma, tig and mig welders who need years of practice to become a pro.

you can use lasers to join different types of metals to each other, including brass to aluminum, copper to brass, titanium to molybdenum, titanium to gold, nickel to copper, and brass to stainless steel.

you can laser weld metal parts of different thicknesses together for all metal joints such as butt joints, t-joints, edge joints, corner joints and lap joints.

the laser can weld aluminum, stainless steel, carbon steel, chromium, titanium and nickel on one side up to 8 mm thick and on both sides up to 18 mm thick. however, the laser can weld copper, brass, gold and silver to a maximum thickness of 6 mm on one side and a maximum thickness of 13 mm on both sides. the 1000w handheld fiber laser can weld metal up to 2mm thick, the 1500w portable fiber laser can join metal parts with a maximum thickness of 3mm, the 2000w handheld laser welder can weld metal up to 4mm, and the 3000w portable laser welding machine can join together. metal sheets with a maximum thickness of 6-8mm are joined together. these data apply to single-sided welds and the maximum thickness of double-sided welds is twice that of single-sided welds.

the handheld laser welder has an emergency stop button that can shut down the welder immediately in an emergency. dual safety light buttons ensure safe operation. the welding gun and optical fiber are safely and reliably grounded to prevent electric shock accidents. all in all, it's safe to operate. but just in case, any operator should take the usual precautions before operating, including wearing laser safety glasses and a protective welding mask and gloves.

lasers come in a variety of welding modes, each with their own advantages and disadvantages, but here are the five most commonly used.

spot welding mode

create the same spot weld.

pulse mode

laser pulses produce lower energy, slower welding speeds, and less heat input.

continuous mode

the laser fires continuously for maximum penetration and welding speed.

High Peak Power Weld Mode

high-power, short pulses penetrate reflective metals.

multi-stage welding mode

repeat positioning or overlapping welds.

turn on the power and laser welder, and observe whether the water temperature is appropriate (usually set at around 21°c, which can be adjusted appropriately between 20 and 25°c according to the situation. antifreeze needs to be added when the weather is cold, and antifreeze needs to be added when the temperature rises liquid. replace with pure water), then turn on the laser switch, select the welding mode according to the metal parts to be welded, set the parameters and pick up the handheld laser gun to start welding. when working, do not look directly into the laser beam with your eyes or touch the laser beam with your hands to avoid injury. if there is an emergency such as water leakage or abnormal sound, please press the "emergency stop" switch immediately. after the work is completed, turn off all equipment in use and turn off the main power switch.