8:30 AM - 6:00 PM

8:30 AM - 6:00 PM

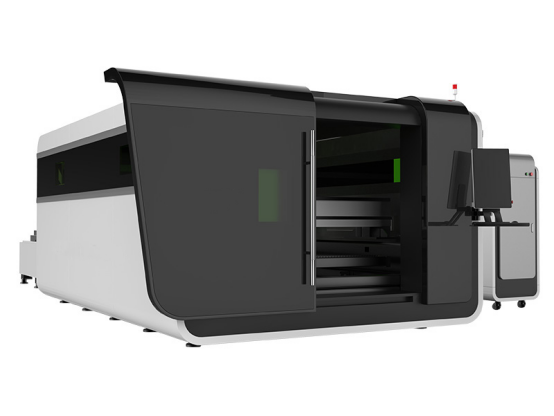

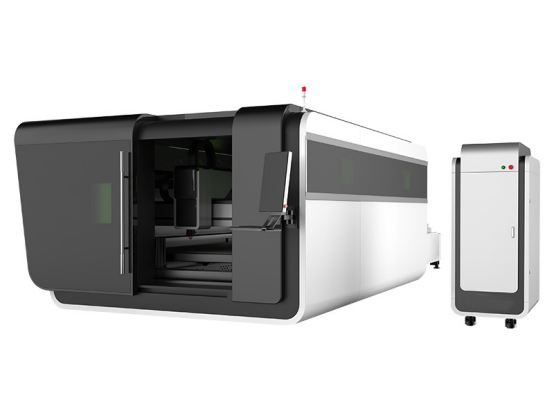

Brand -Eastlaser Model -East4020 Standards -Meeting CE standards in terms of quality and safety Warranty -the entire machine 1 year limited warranty

brand - eastlaser

model - east4020

standards - meet ce standards in terms of quality and safety

warranty - 1 year limited warranty on entire machine

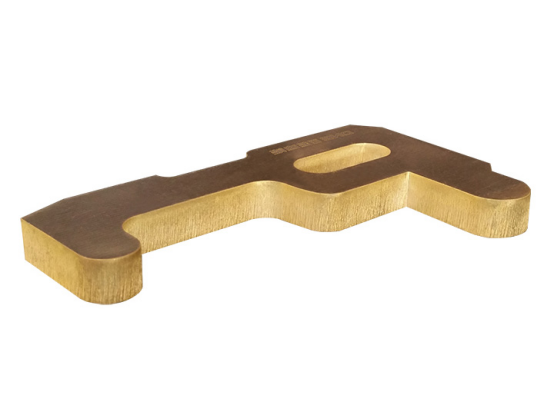

thick metal fabrication is an integral part of industrial manufacturing. in the era of pursuing high-speed, high-precision metal cutting, traditional mechanical cutting tools, such as slower water jet cutting machines and rougher plasma cutting machines, can no longer keep up with the pace of modern metal manufacturing. at this time, a more efficient thick metal cutting tool emerged - high-power fiber laser cutting machine, which is an ideal choice for high-quality metal processing.

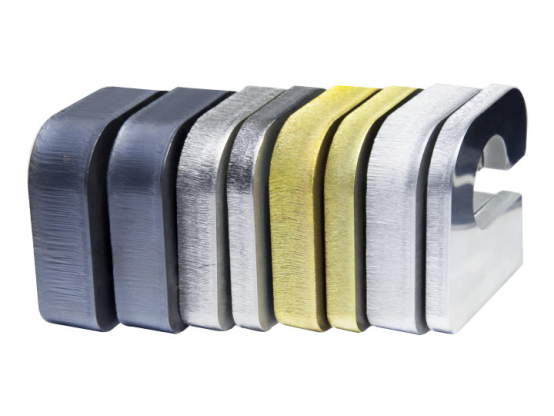

the 6000w fiber laser cutting machine is a metal cutting tool that uses a high-power laser beam to cut complex shapes and contours from metals such as steel, aluminum, and brass with high precision and speed, resulting in clean and smooth edges. compared to low-power laser metal cutting systems, higher-power 6000w laser cutting machines can cut thicker metal and achieve a high-quality finish in less time.

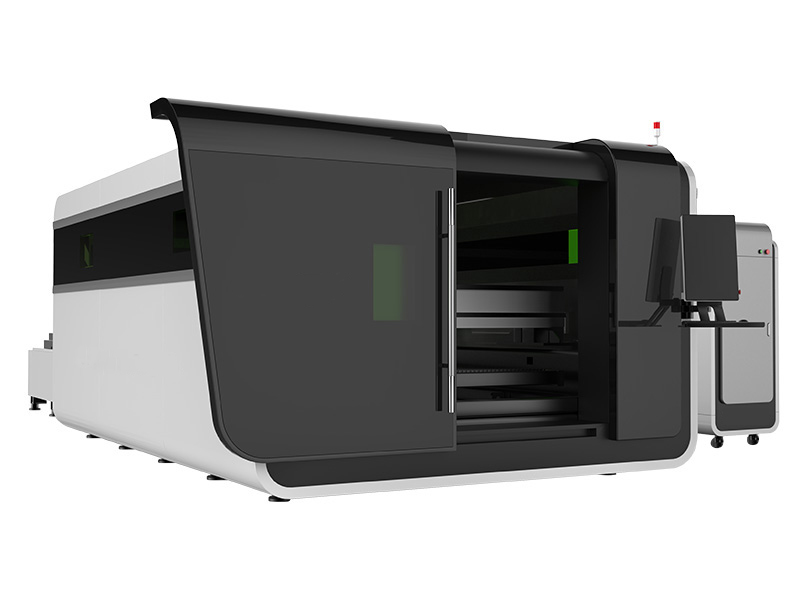

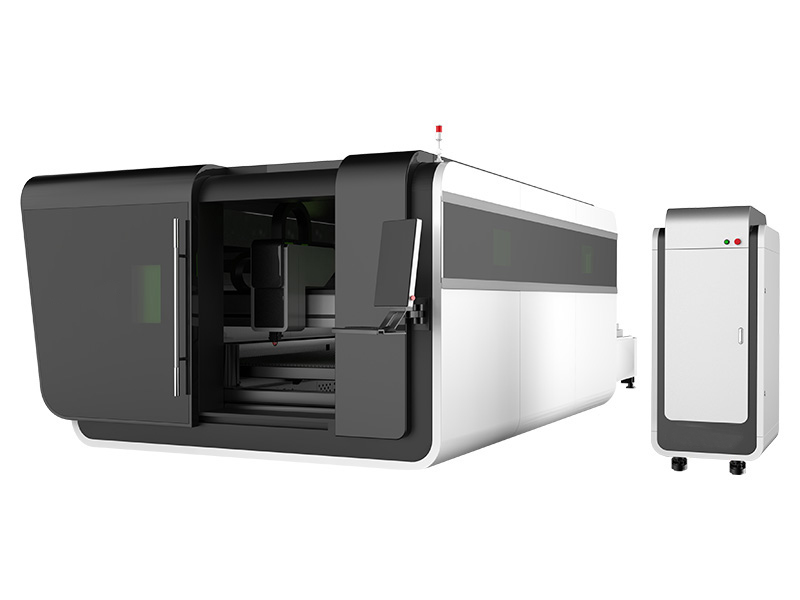

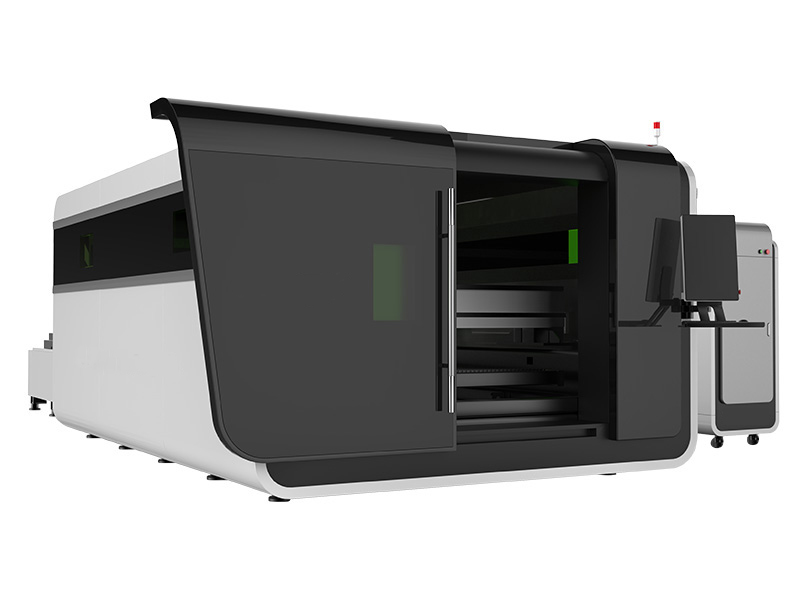

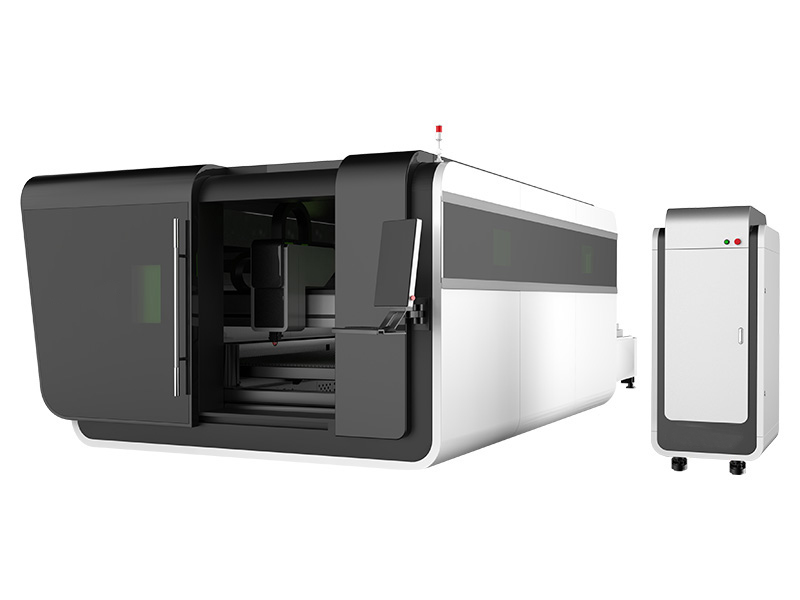

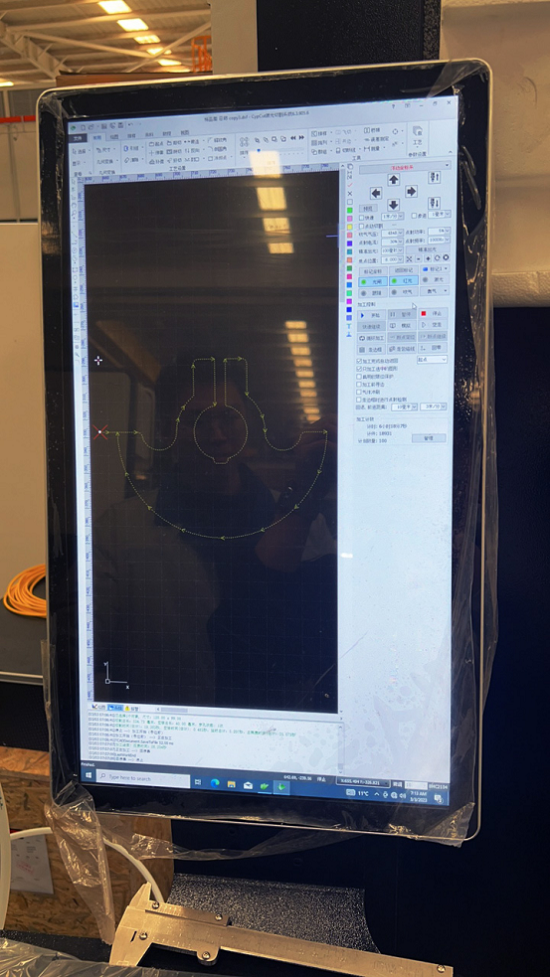

east4020 fiber laser metal cutting machine features a larger full-size 6x12 table, faster cutting speeds, higher laser power - 6000w (2000w, 3000w, 4000w, 8000w, 12000w, 20000w and 40000w), and higher cutting quality, compared to other metal cutting tools. the most advanced ipg laser generator, combined with user-friendly and easy-to-use cnc cutting software, high-strength welded body (made by standard heat treatment and large-scale cnc milling machine), and fully enclosed fire-proof and dust-proof safety protection shell, making it the most ideal for metal fabricators.

the 6000w fiber laser cutting machine is a professional high-power laser metal cutting machine. with an automatic cnc controller, it can easily cut 25mm thick carbon steel, 18mm thick stainless steel, 16mm thick aluminum, 10mm thick copper and brass, up to speed exceeds 60 meters/minute. all in all, 6000 watts of laser power is enough to handle most metal cutting.

• heavy-duty machine tool bed structure design, stable, strong and durable.

• stable and reliable light path system allows continuous cutting.

• easy-to-use cnc controller - beginner-friendly and safe, allowing automated metal fabrication.

• world-renowned ipg fiber lasers with a lifespan of over 100,000 hours, delivering high performance and low operating costs.

• higher cutting quality, higher precision, higher efficiency and faster cutting speed up to 60 meters per minute, resulting in smooth and clean edge cuts.

• well-known high-precision servo motors, lead screws and guide rails ensure efficiency and precision, and increase stability and reliability.

• 6x12 cutting table provides full size cutting for small business and industrial manufacturing.

• 6000w high laser power, capable of cutting most sheet metal.

model | EAST4020 |

work area | 2000x4000mm (6x12 feet) |

laser type | ipg fiber laser generator (raycus, max, reci optional) |

laser power | 6000W (2000W, 3000W, 4000W, 8000W, 12000W, 20000W, 40000W 可选) |

maximum operating speed | 120mm/min |

maximum acceleration | 1.5G |

repeat positioning accuracy | ±0.02mm |

water cooling system | constant temperature chiller |

machine weight | 8000kg |

machine size | 10800*3350*2310mm |

remark | automatically changing workbench, closed cover |

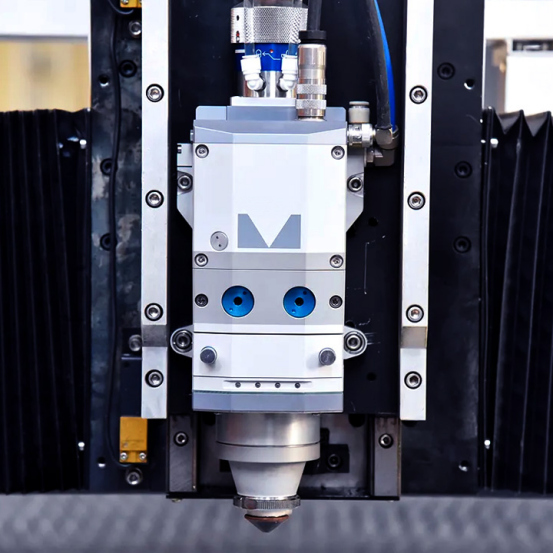

high-precision 6000w ipg fiber laser.

german precitec procutter automatic focusing laser cutting head.

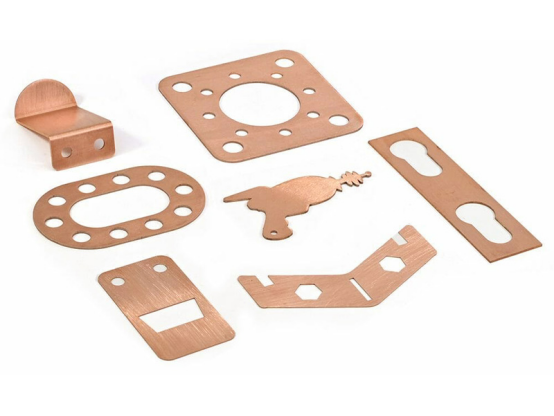

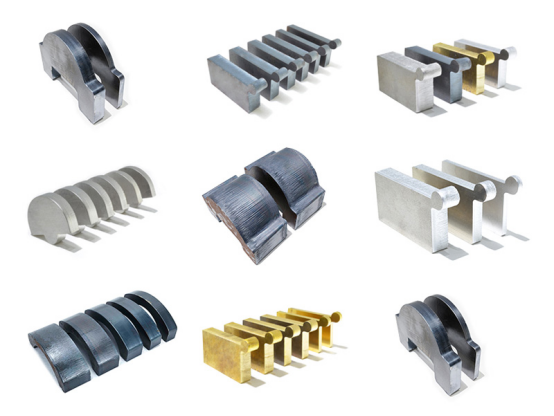

the 6000w fiber laser cutting machine can easily cut stainless steel plates, low carbon steel plates, carbon steel plates, alloy steel plates, spring steel plates, iron plates, galvanized iron plates, galvanized plates, aluminum plates, copper plates, brass plates, bronze plates, gold plates, silver plates , titanium plates, and metal tubes and pipes with rotating attachments.

high-power fiber laser sheet metal cutting machine is used in the production of signs, billboards, led luminous letters, kitchenware, metal letters, sheet metal processing, metal parts, metal labels, hardware products, chassis, cabinet processing, metal artwork, metal crafts, elevators boards, auto parts, eyeglass frames, electronic parts and nameplates.

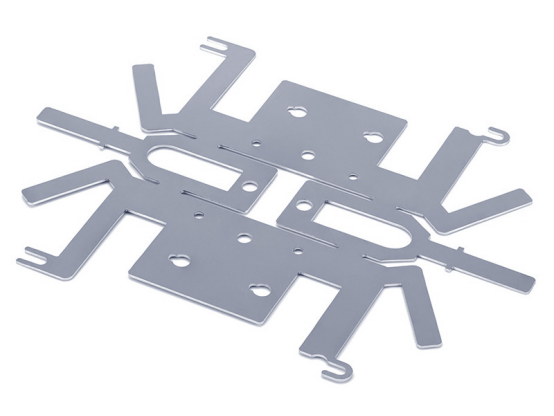

the sheet-tube integrated fiber laser metal cutting machine adopts a horizontal mechanical structure design and can cut metal plates and pipes for a variety of uses. the workbench is easy to replace. it can not only cut round and square tubes, but also drill holes on the forming box.

• cut wires and holes of different diameters from different directions.

• cut the angled portion of the pipe end.

• cut branch tubes that intersect the main round tube.

• cut square, waist and round holes in the pipe.

• cut various shapes and contours on the surface of square tubes.

• cutting metal sheets of different sizes.

• drill holes in the forming box.

purchasing a 6000w high-power laser metal cutting machine that suits your needs and budget is not an overnight decision and requires a lot of consideration. here are 6 easy-to-follow steps to help you purchase the ideal cutting machine for your business.

• step 1. first determine your specific cutting needs such as metal type, width, length, thickness and required speed.

• step 2. research reputable manufacturers and suppliers, comparing features, specifications, costs and customer reviews.

• step 3. consider the cutting machine's warranty, service, and replacement parts availability.

• step 4. request quotes from multiple vendors to make sure you understand the total cost, including shipping and installation.

• step 5. ask about training and technical support options.

• step 6. after gathering all the necessary information, make an informed decision based on your budget and requirements and before finalizing the purchase visit the showroom or facility to check that the laser metal cutting machine with 6kw fiber laser power option is running.